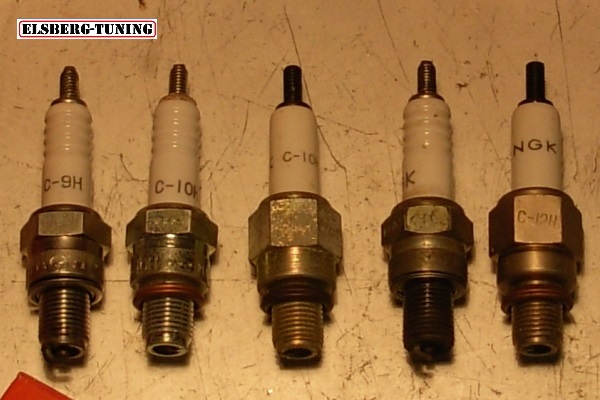

| 2005 season: Got required licence for classic roadracing at Vandel, but due to exceeding the noiselimit by 2db´s ?, it almost did´nt happen. A spectator and Big Honda- fan came to my rescue, offering his CBR1000F roadbike. What a bike! What a guy! Thanks again. Later at an evening training session at Ring Knutstorp, the bike holed a piston at end of straight The search for a colder sparkplug was intensified. Old sixties Honda plug chart showed a raceplug- range between C10s- C14s. A handfull sparkplugs was received just before leaving for a test-and-tune session in Leipzig. Leipzig proved that turning a moped engine into a raceengine isn´t an overnight deal. New problems surfaced, a departing, at speed, belt-tensioner and later an exploding clutch shortened my races. Lesson : Always put the tensioner on loose- side of belt ! |

|

|

|

|

|

|

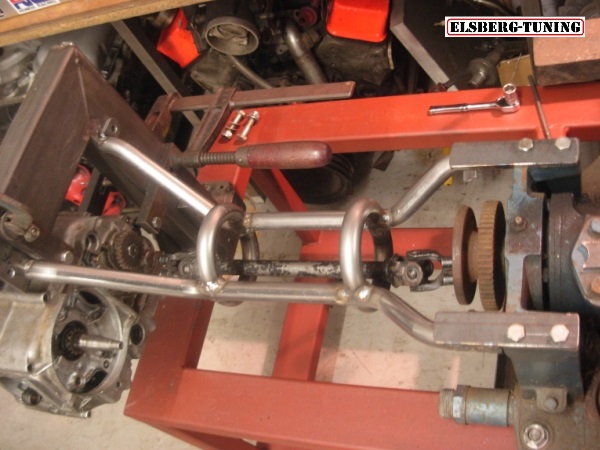

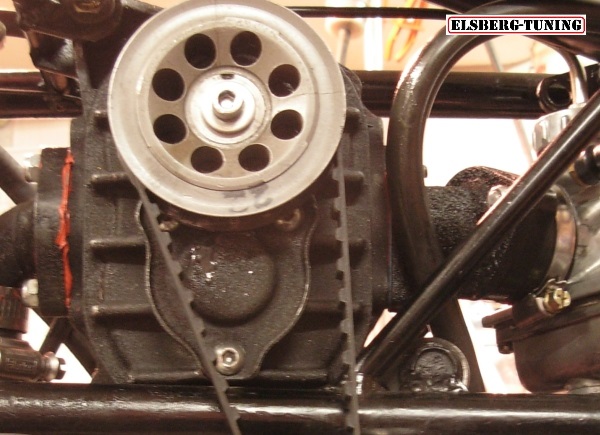

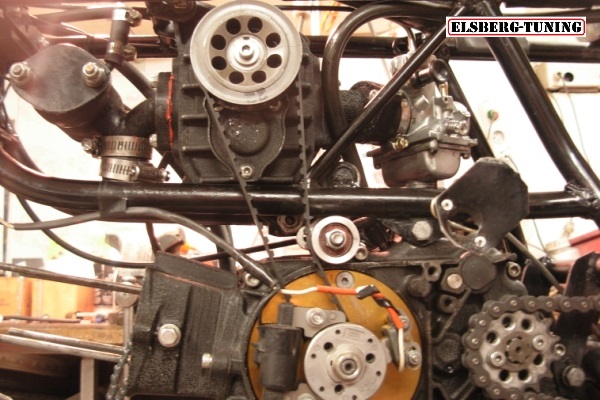

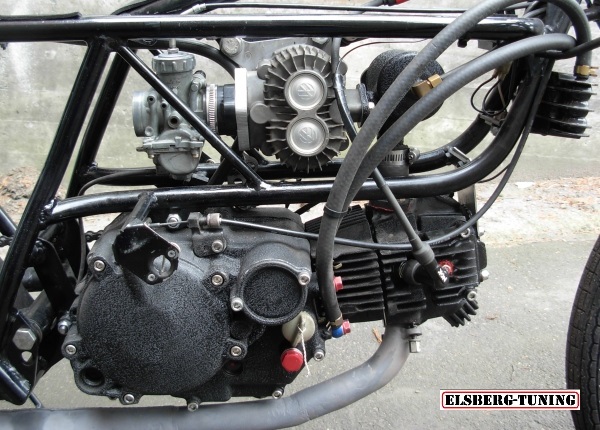

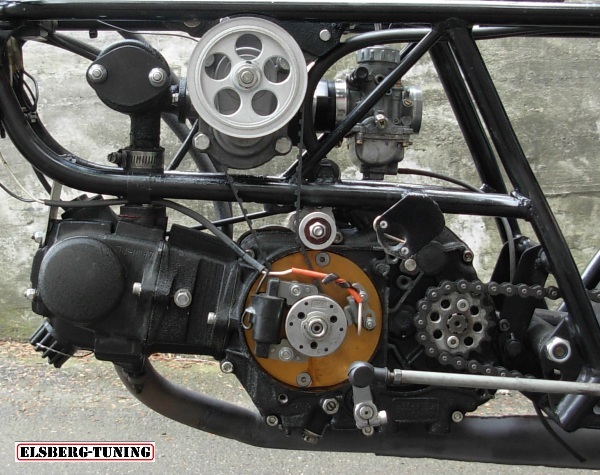

Reconstructed the supercharger drive, remounted carb, and made a smaller plenum, before the 40year- race. The idea was to shorten the drivebelt, reposition the tensioner, and shorten the pass of mixture. Testing on rolling-road, showed progress, but boostnumbers still hovered around 1.3bars. Turning the supercharger slower wasn´t possible due to space limitations, and new palm-sized Roots, were not in sight. With piston crown reduced, and chamber somewhat enlarged, C.R. was lowered to 8:1 leaving combined C.R. above 13,5:1. Not good! Premium fuel, retarded timing, and a 20mm Keihin did lower boost a little, and I must say, improved driveability. Rolling road test reveiled a wider torque- band, 8000- redline, and then some. Rpm limiter wanted ! A lower 4th gear were installed in 2 engines, and as per recommendations, a front engine support, to reduce flex and missed shifts. In Sweden, the increase in torque meant that I hit redline, just into the straight, and before I could do anything about it, the supercharger seized, snapping the drivebelt immediatly. In timed practise, the engine started to feel rough, and I headed for the pit once more. Metal shavings in the oil meant disaster, and later a well chewed cam- chain tensioner wheel, reveiled itself. Managed to get ready for the main race, The spare engine sounded real good, and the last supercharger turned freely. I felt good about it, but during the warm- up lap, I lost two gears, first and third. Start in second, and up to fourth, slower acceleration than normal, but not much! The engine pulled like never before, and I actually gained on the twostrokes ahead, it pulled hard on straight and reached 12700rpm in topgear. Half a lap later I ran out of fuel !!! Blamed the pit crew offcourse. With present gearratio, that equals to 142 km/h, an okay speed for a stock- cammed moped engine with a little boost! End of season 2005! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

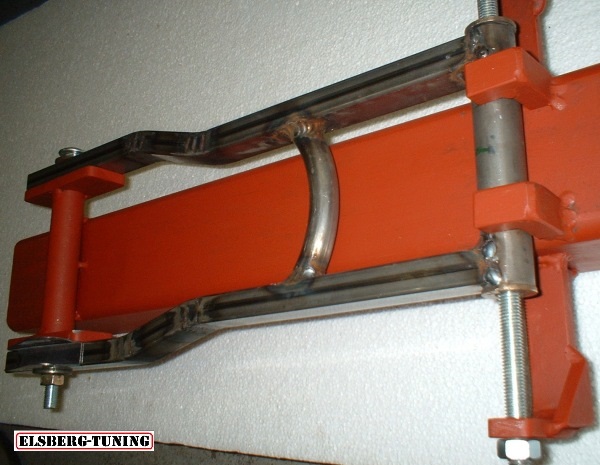

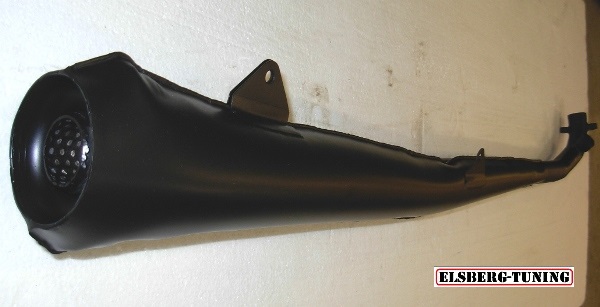

Picture at left shows the new improved silencer/megaphone for the Honda. Exceeded the limits last time out so an update were needed. When compared to the usual method: rolling several cones, welding them individually, and then piecing them all together, hydroforming is a clean way to shape a silencer, and faster too. The technique goes like this: |

|

|

|

|

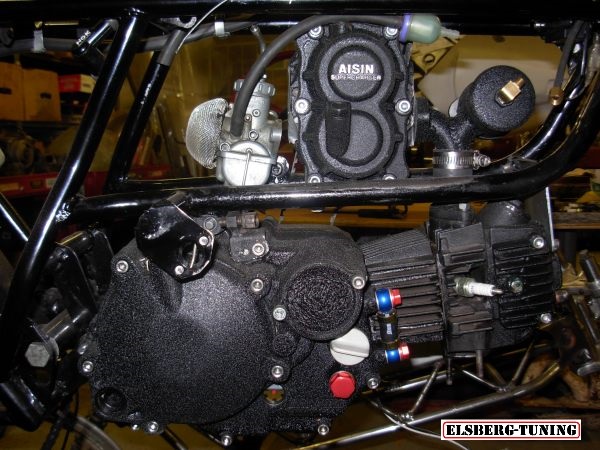

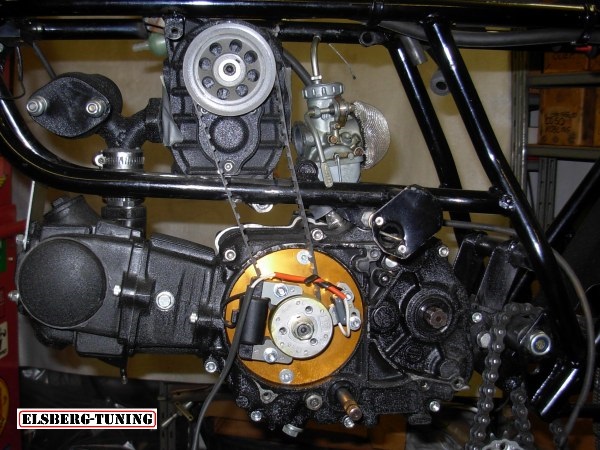

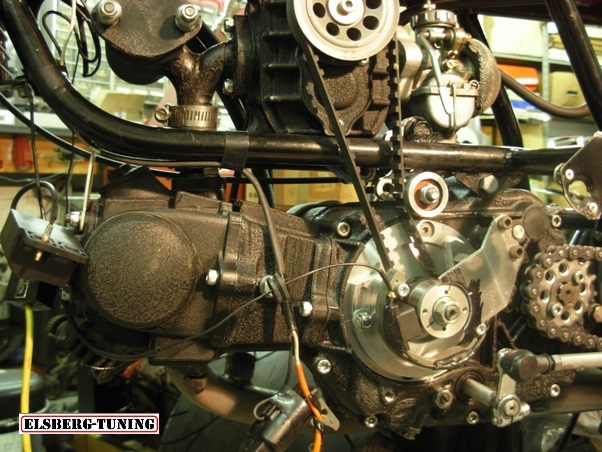

The Honda CD50 engine is with its 39x 41,4mm and a single cam, not exactly what you would call a high winding screamer, but nonetheless chosen because its cheap and plentifull. A plethora of speedparts exists for this engine- family, due to the fact it has been in production since 1965, and still is!. But most tuning equipment concerns increases in cc´s, mostly done by a bigger barrel: a 51mm barrel and piston can be fitted without modifications to the crankcases giving 80cc + with stock crank. The challenge for me was raising the power- level without exceeding 50cc and a supercharger enhancing midrange torque, keeping this longstroke- engine revs at a sane level. Collected a lot of different small superchargers and realized that all of them were oversized for the job, but I managed to reduce one by two- thirds by cutting and welding. With a 3: 1 drive ratio this blower gave ½bar of boost at 8000rpm - perfect for a start. And this year I got an opportunity to try out the new combination, as a big classic racing event were scheduled at one of our oldest tracks here in Denmark. Hastily a lot of small improvements for the bike were planned: 35mm lowering of the bike, stiffer rear shocks, seat moved 100mm rearwards, and a more efficient silencer. The weather were perfect for this time of year, and the track was different from what I have tried before. I would call it a four- stroke track, as the strong engine- breaking made my Honda drift into the corners, helping to a tighter radius. Some two- stroke drivers were surprised by this luring track, with its blind corners, and some did outbrake themselves into trouble. I was lucky meeting up with another Honda driver, Dutchman Wim Heeroma on his fine 89cc Dream 50r, who challenged me throughout the weekend. His relaxed driving- style gave me an advantage in the corners, but on straights he would gain on me - fantastic! All Saturday I kept the 3:1 ratio on the supercharger drive, but in the evening Wim told me he would remove all silencing from his megaphones for Sunday, and by that gain 10% in power! Wim new what he was doing - that old fox, immediatly I increased the supercharger drive to a 2,5: 1 ratio which raised the boost from ½ to 1bar. That resulted in a 3second gain/ lap and Wim couldn't equal that speed. But from experience I know that 1bar is close to the limit on these engines, and quite surprised when the engine went through Sundays training without complaining. Feeling confident before the race about this bulletproof setup, until the engine let go on the warm up lap - like so many times before. End of season 2008 Specs for the 2008 season: Honda CD50 engine 39,25x 41,4mm, severe ported standard head with standard sized valves, stronger valve springs and a SS50 camshaft (from the 6.25hp model), sectioned Aisin AMR300 Roots style supercharger fed by a 20mm Keihin, oilcooler, standard four- speed transmission with a reduced fourth gear, and an aftermarket clutch (not crank- mounted like original!) Guesstimated horsepower: ½bar ~8hp and 1bar 9½hp at 13000rpm. Redline: 13500. Usable torque range: 8000- redline. |

|

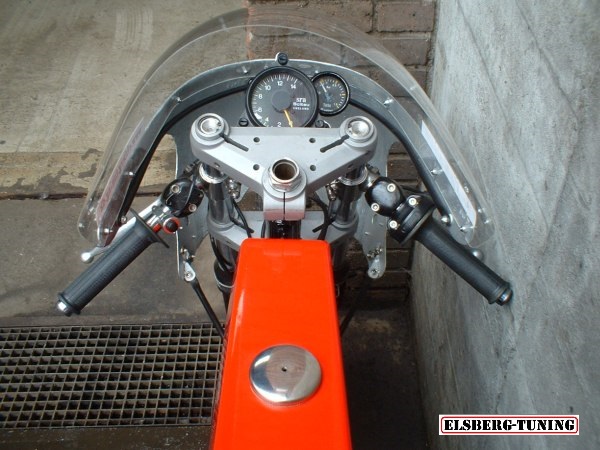

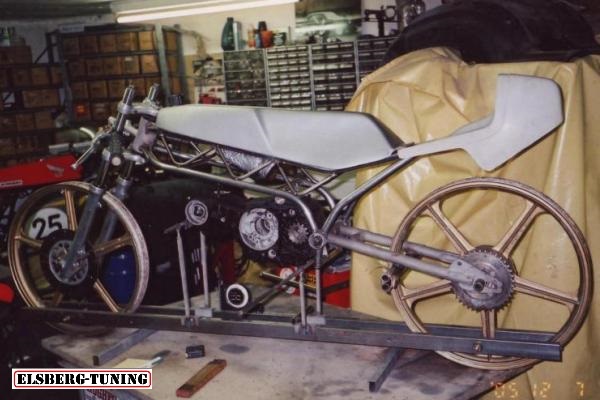

| Watch this bike! |  |

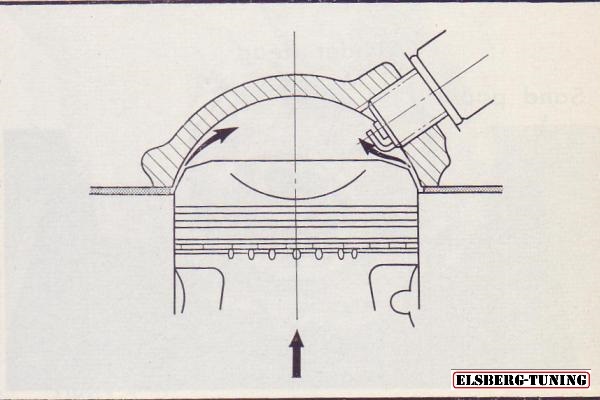

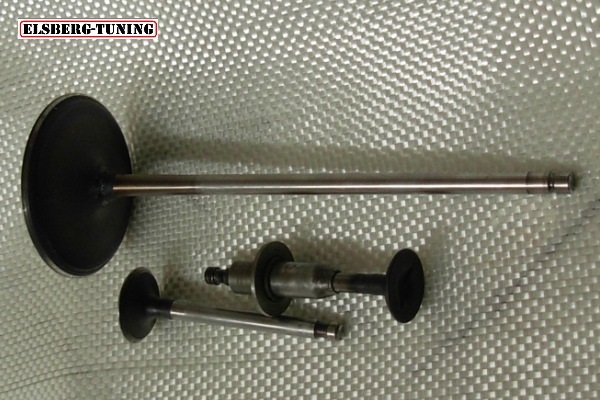

| Before the 2009 season (read: a single race meeting in Sweden), I had used most of my spare time finishing the Kreidler racer, but a quick fix for the Honda was needed! A thorough search for a preferable forged, low compression piston, had come up with nothing, so plan b was activated. Honda made a lot of 50cc engines with different bore and stroke combinations and the P50 had a flattop piston with the right pin- size as well as pin height. But, coming from an engine with a larger bore meant I had to exceed the 50cc volume by a whisker - don´t tell anyone! |

|

|

|

|

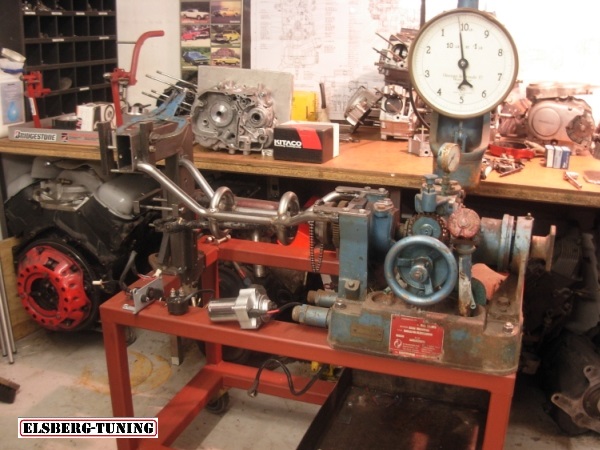

With the P50 piston installed, a compression ratio of 6,2: 1 was reached. So far so good! That meant ignition timing could be sligtly advanced but by using a flattop piston, the squish- band was disturbed, and I expected some kind of counter- reaction. Normally a dished- piston would be the better choice, but time didn´t allow such tests. About tests, I have plans for thorough testing through use of an engine- dynamometer. An invaluable tool that allows you to connect every imaginable instrument (a thing you possibly cannot do during track-testing!), and recently I purchased this Heenan-Froude DPX0 water- brake. This tiny table- top dynamometer, handles engines with outputs less than 60hp and thus covers my current need. The similarity in design of the Honda CD and Kreidler engine will simplify the mounting of engine on dyno. |

|

|

|

|

|

|

Planned for 2010..or 2011: Modifying crankcases to house a 6- speed transmission. Test of a special- made piston of the flattop- variety, reducing CR to 6- 6,5: 1! |

| Update on the Honda: The last two outings revealed that this rev- happy engine must be kept below 12500rpm. Following that practise, and the damn things drives through it all! Tried another mix of race- gas and had no signs of knock with a 1bar boost setting - all good! Looking forward to the next session :o) Last race this season and again no sign of pinging - time for an increase in boost! |

|

|

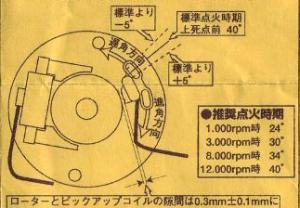

Increasing the boost necessitates an alteration to the ignition timing, to decrease the ever present danger of detonation. I have attached a chart showing the curve built into the Kitaco inner rotor ignition mounted. As you can see it just keeps on advancing. And no boost retard. I have been running this curve all these years knowing it was no good for a supercharged engine! The only reason for retaining it was lack of time and mechanical trouble elsewhere :o) |

Raising boost means increased combustion- pressure, and a weak point in supercharged engine is the head- gasket. A simple mod is o-ringing - a groove is cut into the face of head or cylinder, and a stainless steel wire is inserted. This wire must be placed just outside of the head gaskets compression- ring, protrude the surface no more than 25% of gaskets thickness. |

|

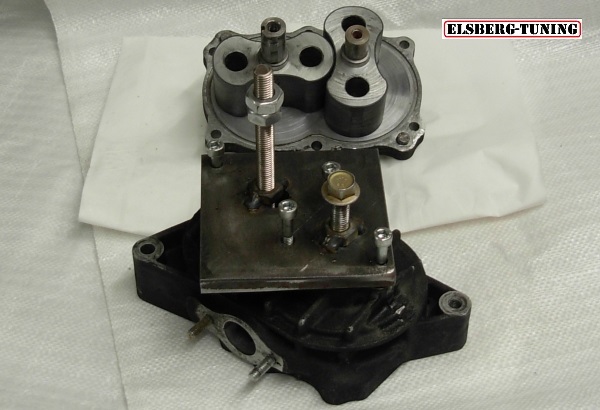

| Disassembled the Aisin supercharger in search of a leak, as I tried to step up supercharger drive ratio and saw no gain in boost! I have been running this Aisin for some years now and I have noticed both an oily intake and grease being pushed out of the bearings - clearly indicating that the rather flimsy seal- lips on a double sealed bearing doesnt handles high boost very well. Disassembly showed un- seated seal-lips, which proved my point. Maybe the overall state of the bearings caused the leak so a fresh set of bearings went in. Enlarging the inlet of the blower and stepping up to a 24/ 26mm carb made boost figure jump from 0,8 to 1,2bars. |

|

|

With new bearings installed a high- boost run revealed the issue: on the gas grease being pushed out of driveside- bearings - off the gas, and super- charger gearoil being sucked in and burned! |

|

|

| I´m not sure that the Aisin is suitable for high pressure supercharging! The compact design of the AMR series is a result of using sealed bearings - no "real" seals! Having said that I must emphasize that seals in a Rootes- type super- charger live in a difficult environment, as half of the chamber sees vacuum and the other pressure. As the chamber is devided pressure- wise along the seals - well, you get the picture! In bigger Rootes type blowers a typical lip- seal is placed alongside the bearings, right next to the chamber. They are mounted with the lip pointing at the bearings and in that way allows some boost to sneak into the bearing- housings, but in vacuum not inhaling any oil! You dont want oil in the gasflow as it lowers the octane of the fuel. I may have to look into using another blower - the rare VW/Porsche pump looks appealing right now - having proper seals :o) And without any further delay a new blower was installed, and now the race against time is on again, as THE big Classic event is coming up! Classic TT 2012 - 8- 9 September Ring Djursland. |

|

|

|

| 1bar+ readings and lots of trouble! Serious cutouts at WOT which no jetting, carb size and ignition adjustments could remedy! Had to re-install last years setup for the RingDjursland event! Engine developed some annoying cut- outs during the race and laptimes were 1,5 seconds slower than the Puch´s! Next year! |

|

|

|