Much needed update of the current market for small engine superchargers. |

|

| The market for secondhand superchargers are also bigger than ever - just try to do a search for "supercharger" on the bigger on-line marketplaces. Sub- one- liter superchargers are still rare, but do hit the surface once in a while! |

|

|

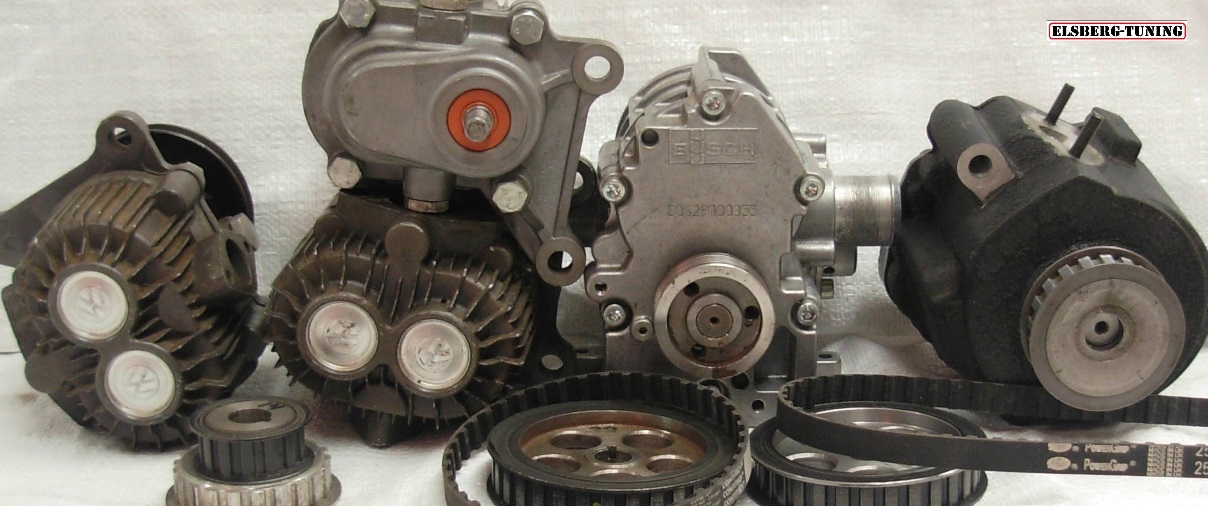

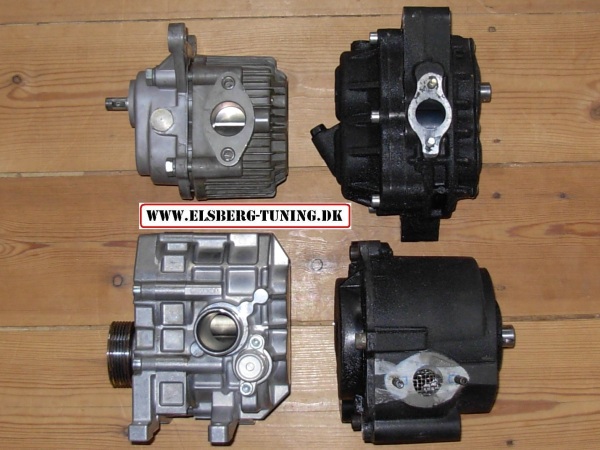

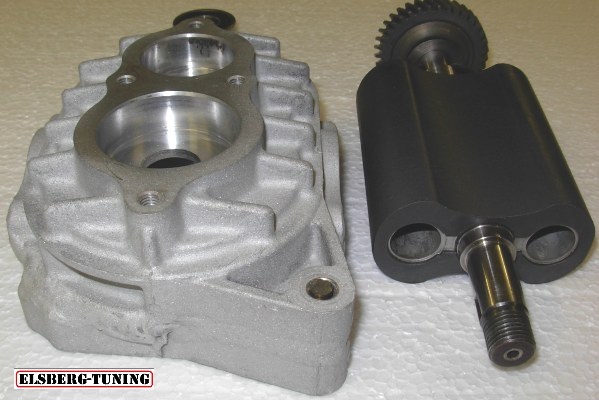

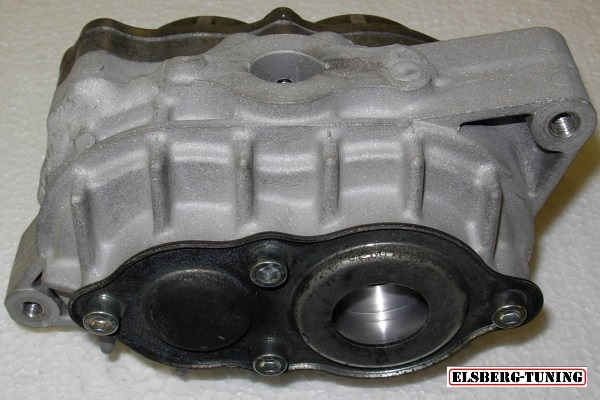

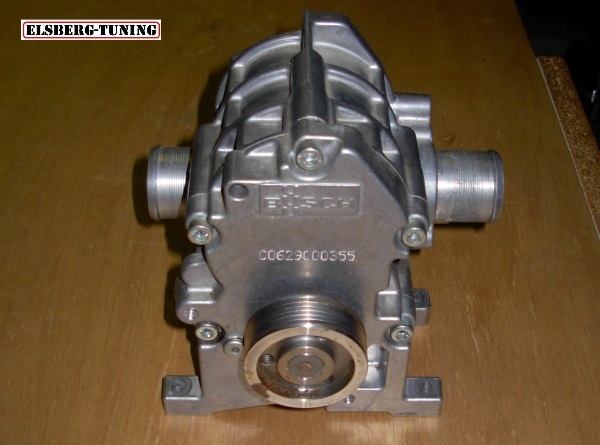

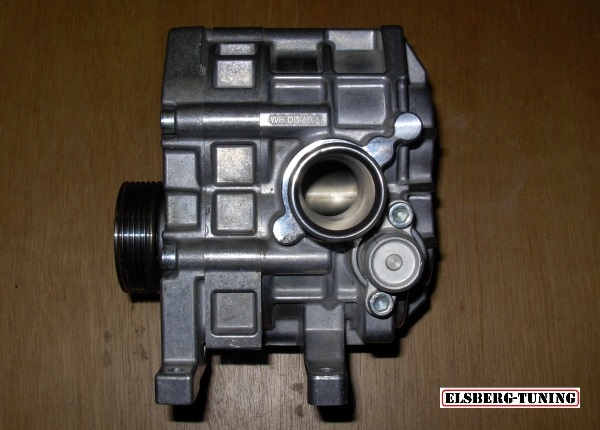

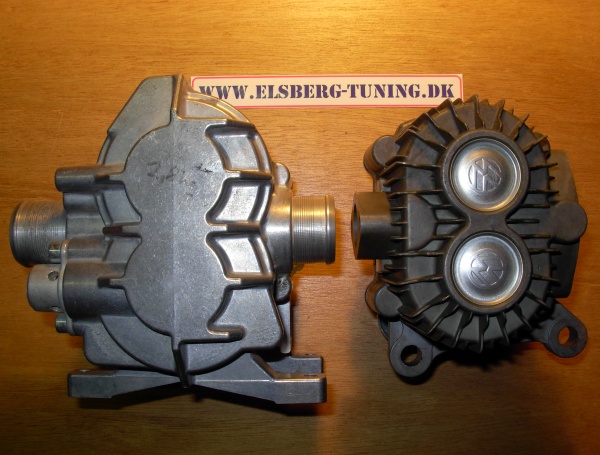

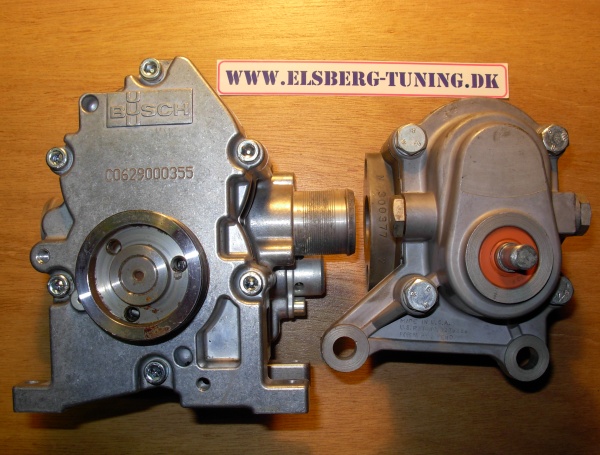

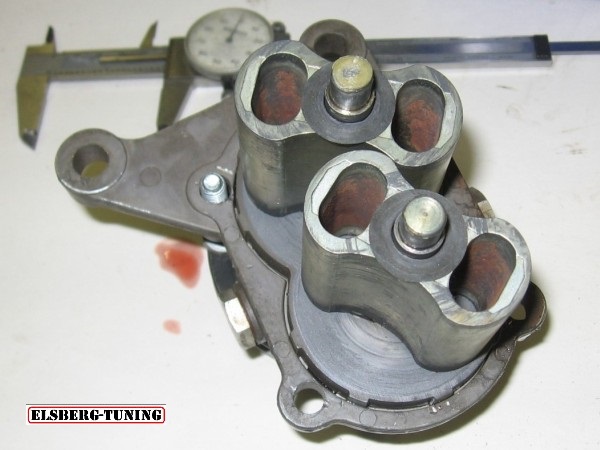

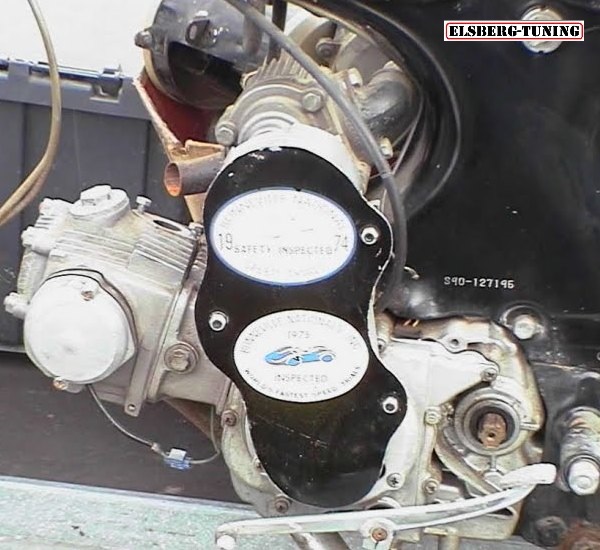

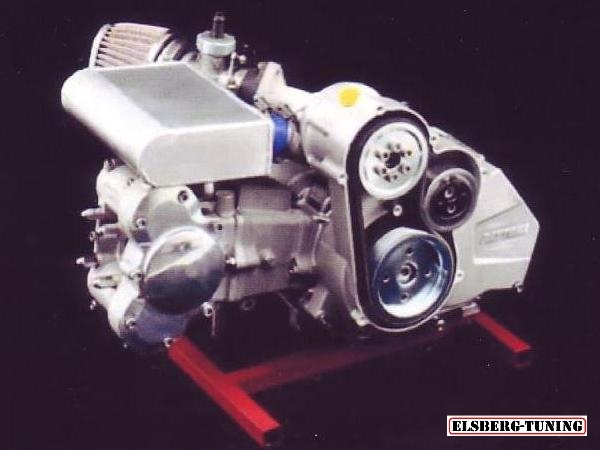

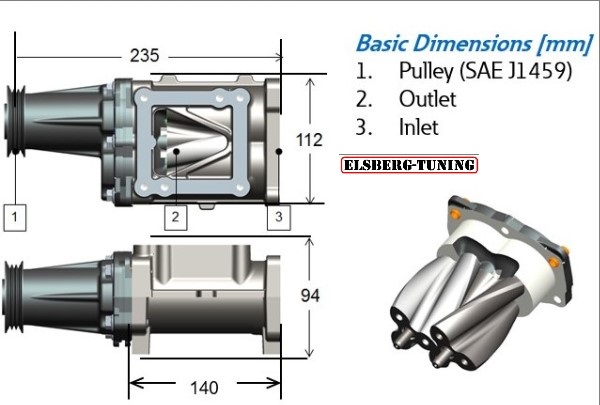

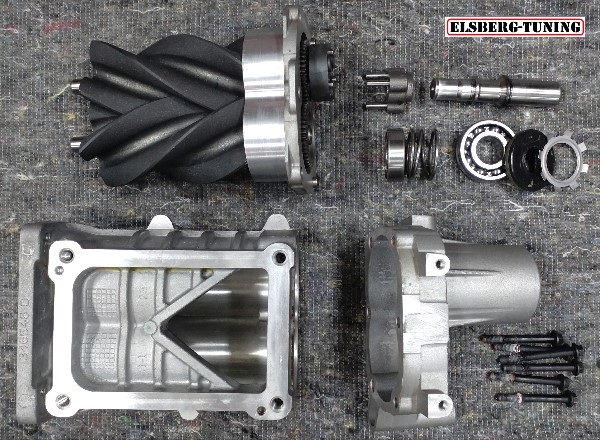

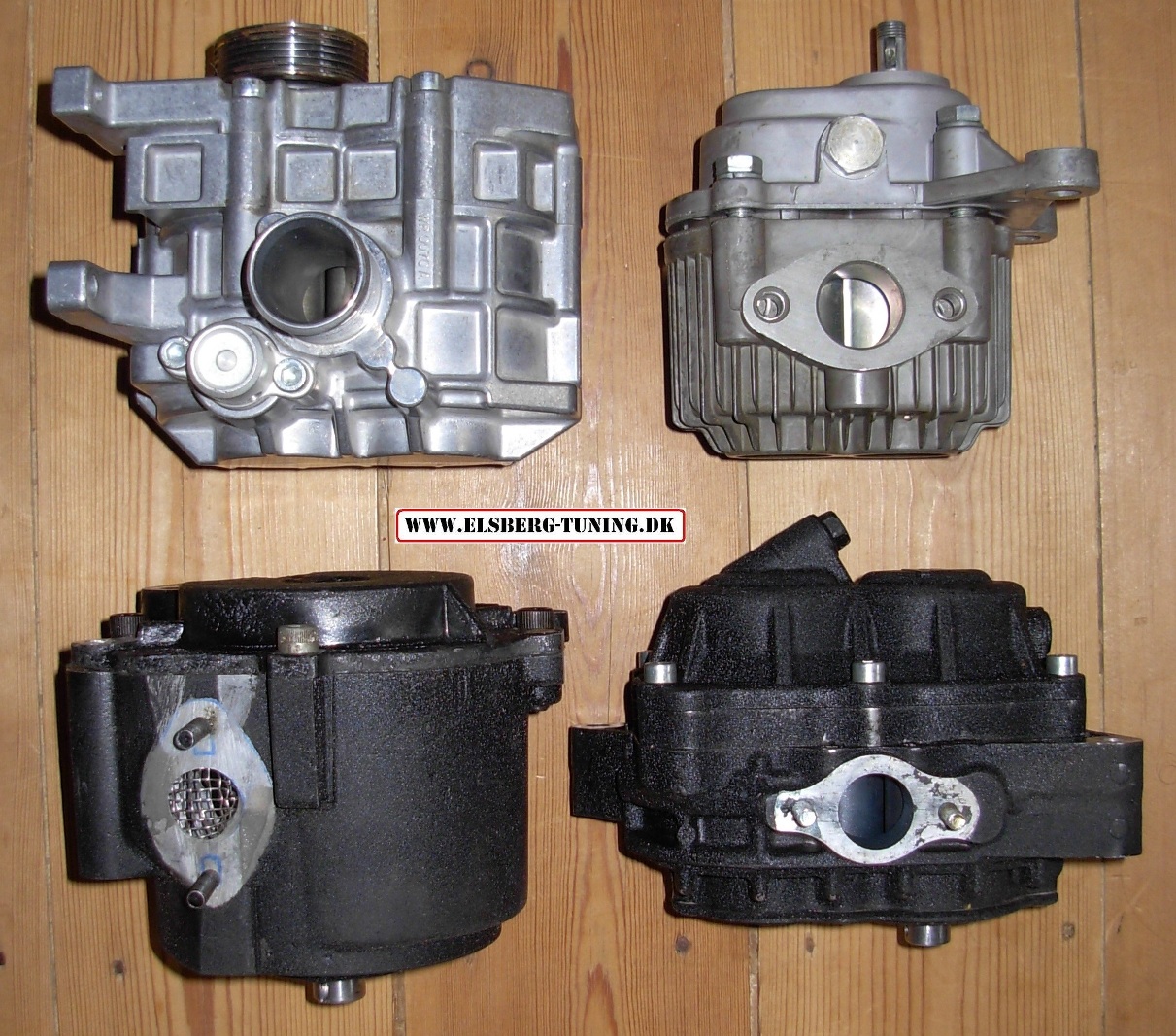

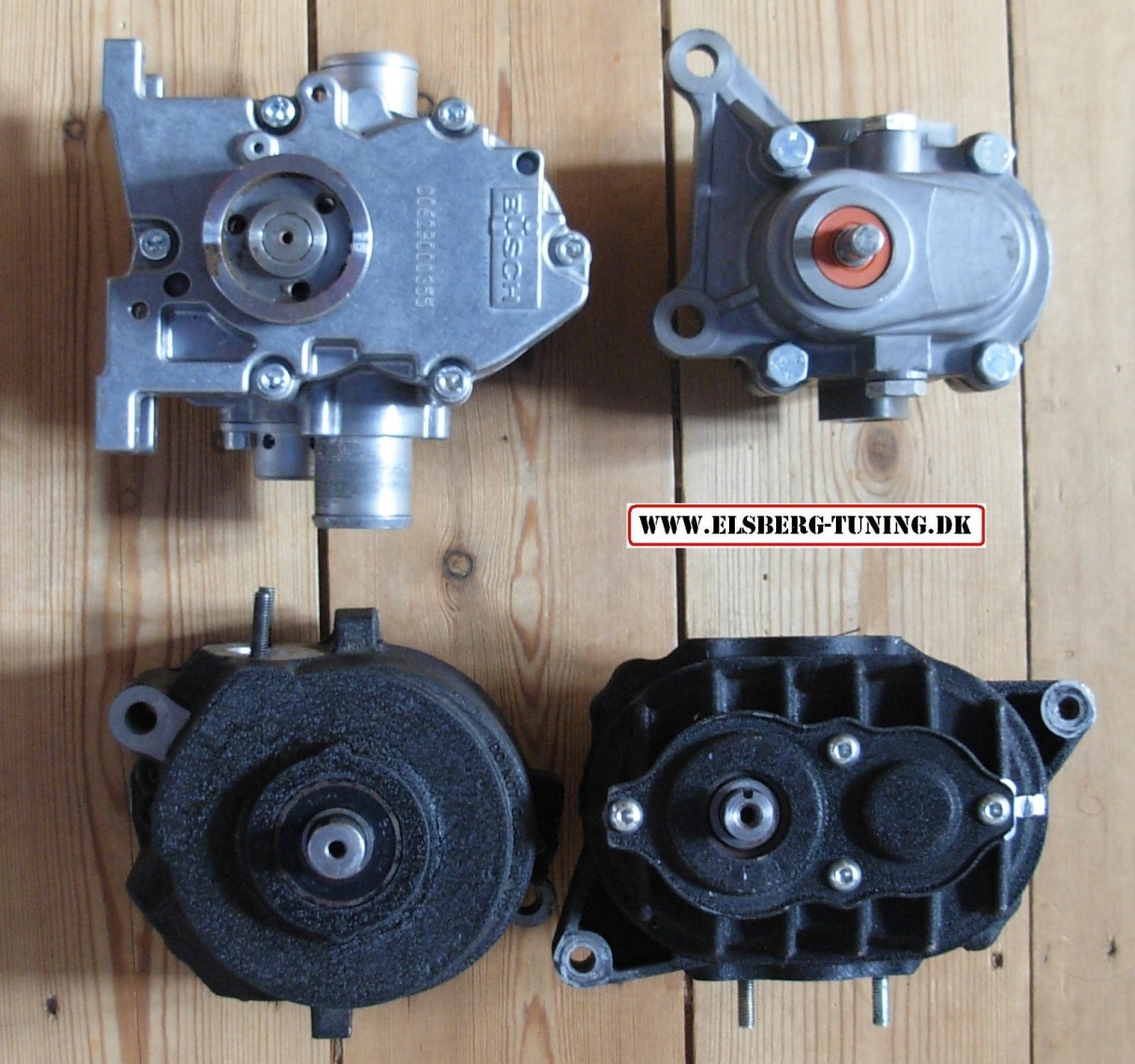

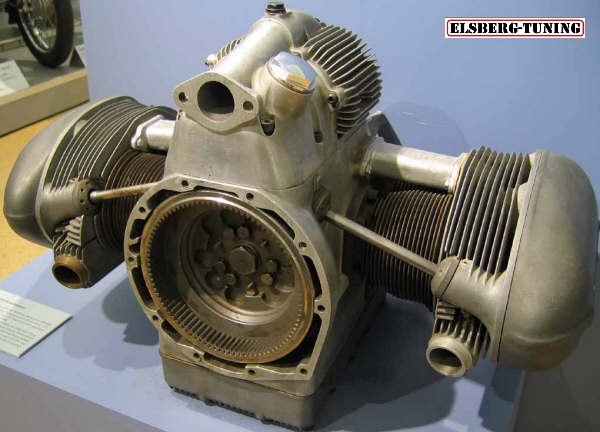

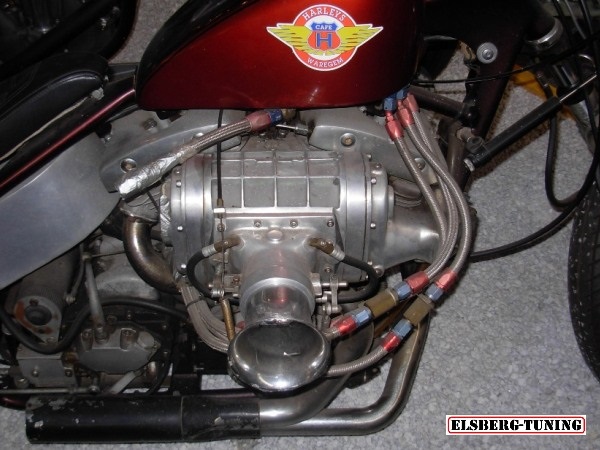

Superchargers small enough to be suited for 50cc engines are rare and far between. You can use a too large charger, but results will not be satisfactory. Some superchargers can be reduced in size - more about that later! You have to turn the charger at a lower speed than the engine itself, by reducing the driveratio, sometimes as much as 4:1! Following pictures shows 8 of the smallest superchargers around: The smog pump - cheap and plentiful. Used on automobile engines since late sixties. The Aisin AMR300. From Subaru Kei- car - 660cc supercharged citycar. The KF Max10- 25. American aftermarket blower. The Hansen V12. Made especially for supercharging Kart- engines from 5- 20hp. The Busch/ Peugeot Mounted on the Peugeot Jetforce and Satelis 125cc scooters. The VW/ Porsche smog pump. Mounted on models destined for the American market. The Daytona superchargerkit. Will hit the market ???. The Ogura TX01 and TX02. Japanese Roots pump. European- made Do-It-Yourself supercharger kit! Read more below. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Japanese based Daytona company worked to launch a supercharger kit for their 125cc Monkeybike engine. Their Youtube video shows a well thought out system of the suckthrough type, and the plenum even has an intercooler added! The supercharger itself bears a strong resemblence to the Danish- made Rotrex C15, which uses a planetary-traction drive, to gear up the axle rpm leading to what equals to the compressor- side of a turbocharger. Visit: www.rotrex.com/Home/Technology/Product_Technical_Data.aspx The supercharger has a built- in oilpump, and an added oiltank supplies the high- rpm running supercharger with filtered oil. |

The Daytona supercharger video: First test drive. Latest video. |

|

|

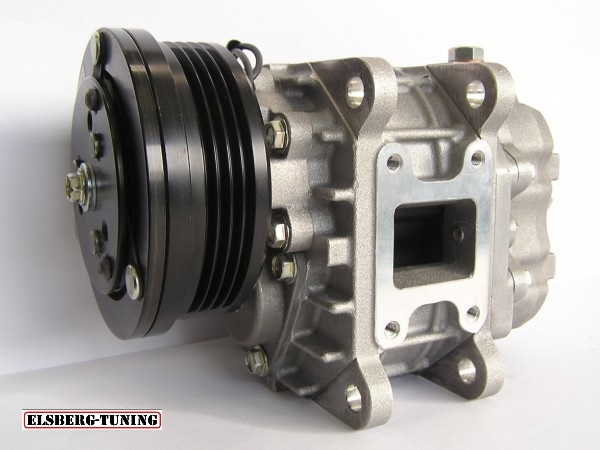

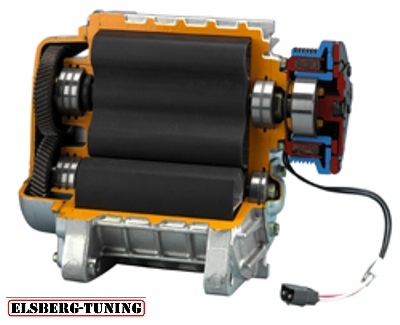

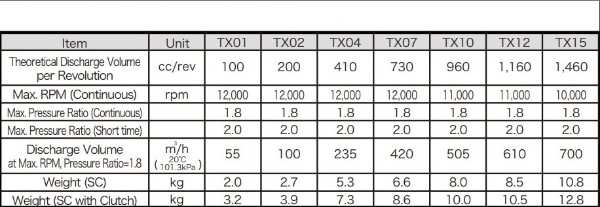

| The Ogura Industrial Corporation manufactures a line of Roots style pumps, and the TX01 and TX02(100cc/rev and 200cc/rev) is just what the doctor ordered! |

|

|

|

|

|

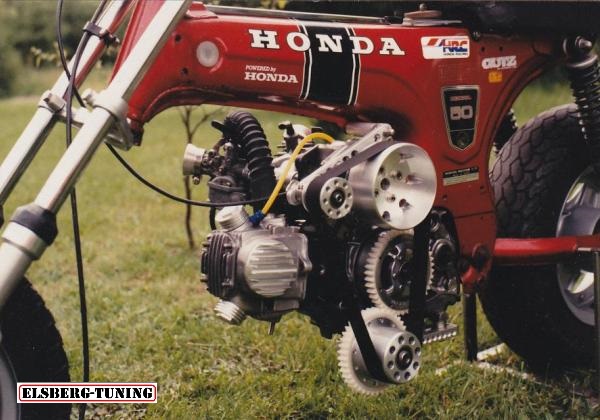

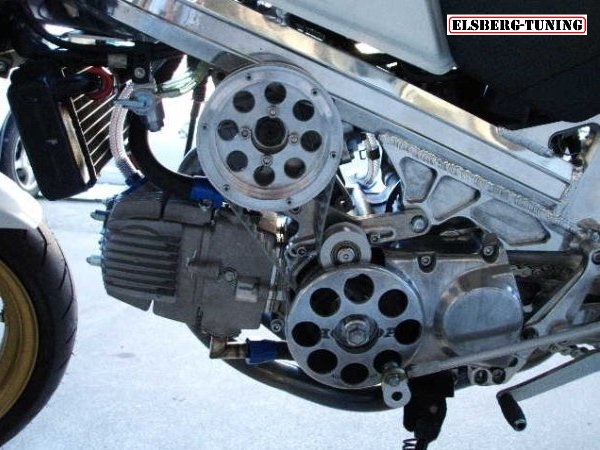

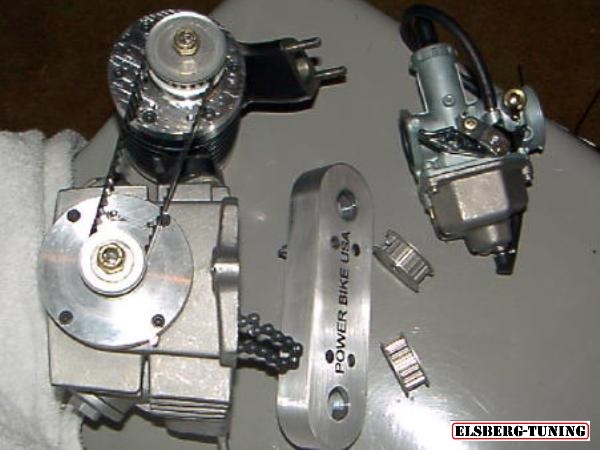

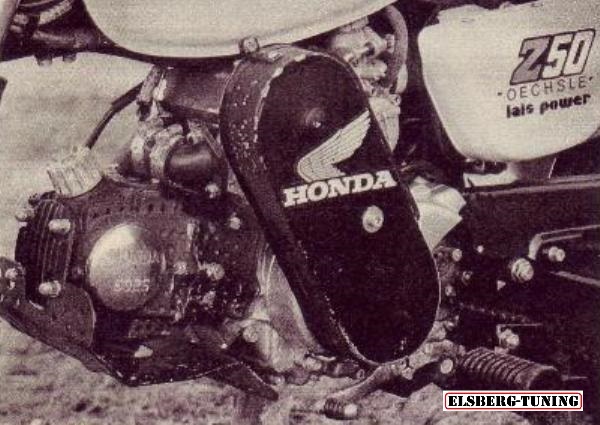

| Very interesting Do-It-Yourself superchargerkit manufactured here in Europe?. A supercharger kit for 50cc-125cc stock motorcycle equipped with the Z50/AB27(horisontal)Honda style engine. Links: http://youtu.be/HzKl4gpYK3o s-charger.ca |

|

|

The supercharger is a vane- type and emits the most adorable blower-whine ever heard from a moped engine! It comes in various sizes meant to cover engines from 50cc to 125cc. Lets hope for mass- production which will result in a reasonable priced kit. |

|

|

| A term often used when dealing with carburetted engines, which describes the placement of the carb in relation to the supercharger. If you mount the carb between the supercharger and engine, you have a blow through arrangement. Leaving the carb in its original mounting seems easy, and attaching a hose from the supercharger to the airfilter flange. A troublesome configuration in most cases, because in a blow through setup the carburetor sees both vacuum and boost, and the transition which takes place when opening the throttles, makes carburettor tuning very tricky! Sometimes its necessary to encapsule the carburettor completely, to avoid fuel bowl getting emptied by boost! Another issue is the dry- running supercharger, which in my experience is a bad thing. Running mixture through the supercharger does have several advantages, as it "seals" the rotors at ends and tips, making it pump more efficiently, and another bonus is a reduction in the charge- temperature. And I have to mention that I in several cases have seen an increased mileage in no- boost situations, when running the blower "wet", which leads me to think that the whirling rotors have an effect too, as they "atomize" the charge into smaller particles. |

|

|

|

|

|

|

Advantages when using the blow- through setup are that boost- pressure regulation can be handled by a simple spring loaded valve, which just dumps excessive pressure to the outside. Those adjustable wastegates that are mounted before the turbo, in a turbocharged setup, will work just as well in a blow- through supercharging setup. |

| A necessity in any suck- through installation is a pop- off panel or valve. A spring- loaded device opening a window big enough to let out excess pressure, in case of a backfire. It is neither a wastegate nor a BOW (blow off valve) and is a serious matter due to the amount of mixture present in the intake system, which now has a much larger volume. On a normally aspirated engine a back- fire will ignite the charge present in inlet passage only, (you hear a slight pop from the carb) but in a supercharged engine the charge in the volume of the supercharger and plenum must be added, and when it happens - well, you will know!. I have seen pressures as high as 60bars in a backfire, and that will do short work on gaskets, seals, airfilters and throttle valves, which occasionally turns into artwork! Adjust the pop- of valve to open 0,5bar above your boost setting. I usually make the outlet roughly the same diameter as the carburettor bore, cover is a piece of aluminum with a o- ring groove sealing outside the outlet. If you glue- in the o- ring, there is a big chance it will stay in place during a backfire and this will allow you to drive on. If the pop- valve dont re- seat after a backfire, your engine will have a major vacuum leak, and behave erratically until fixed. |  |

|

|

|

|

|

|

|

|

|

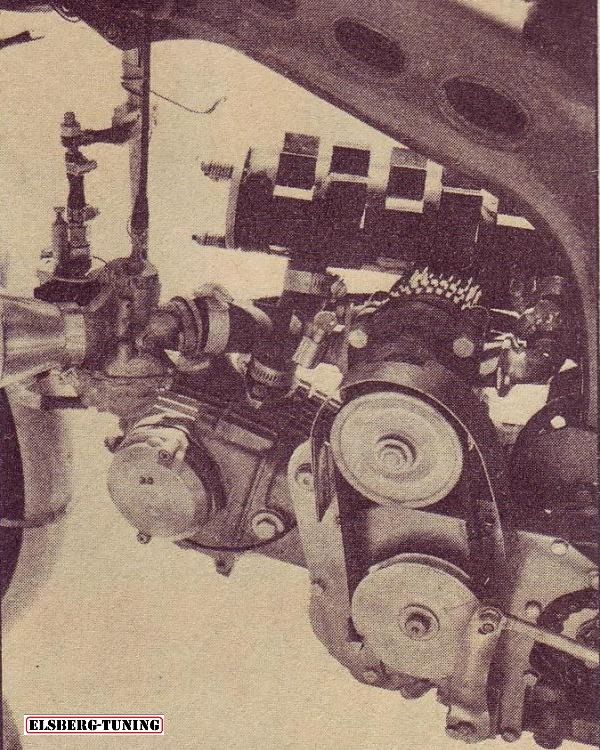

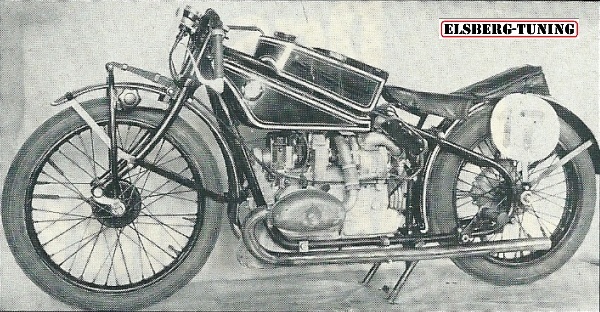

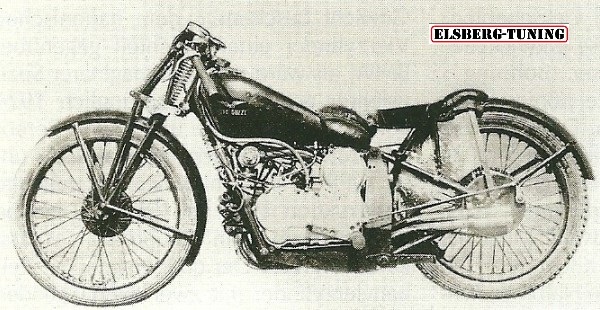

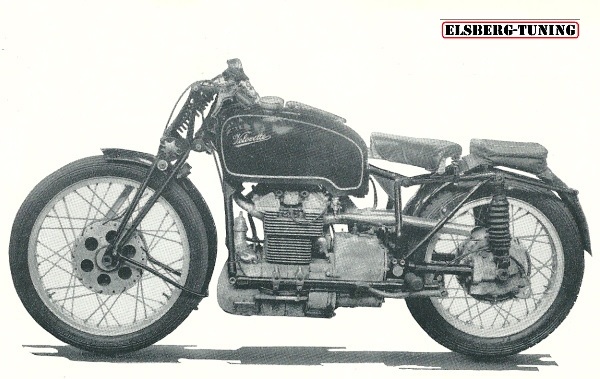

Around installation one should mention, that this picture is all wrong! Those who have driven a supercharged motorcycle knows that installing a supercharger, that are bigger than your brakes, is a no- no!!! One thing is correct though, namely the placement of the supercharger. Compressing air means heating it, and placing the supercharger in front of the engine is a very good way to cool down the intake charge. If this is not an option that will work for you, second- best solution is to mount the plenum/ intercooler in the airstream. |

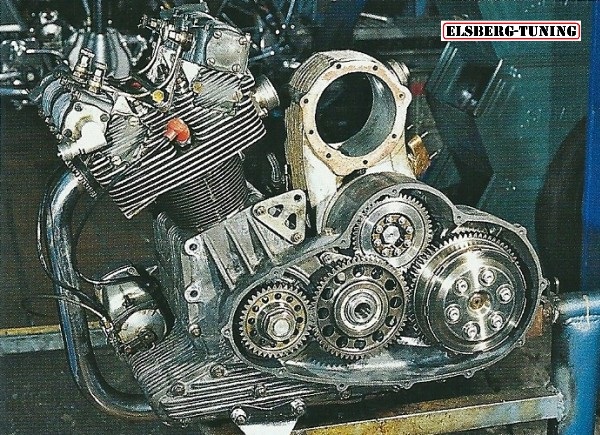

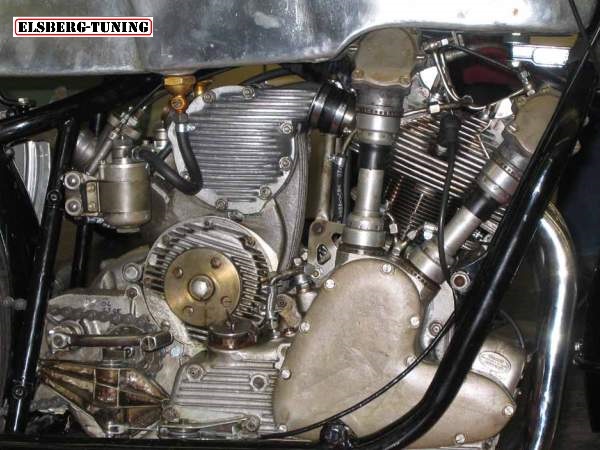

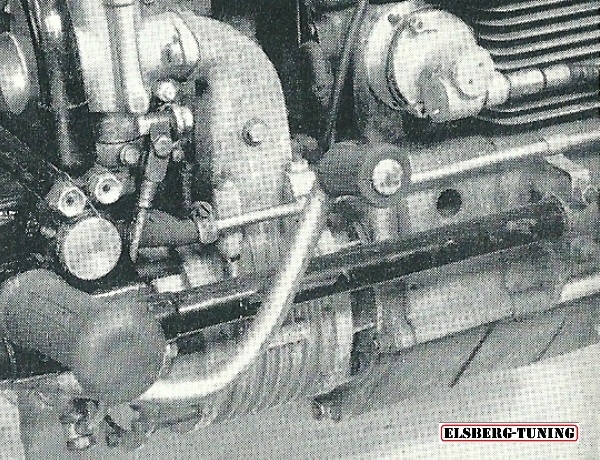

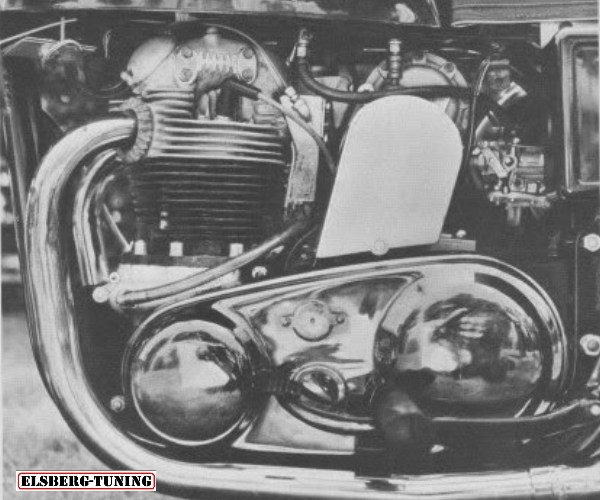

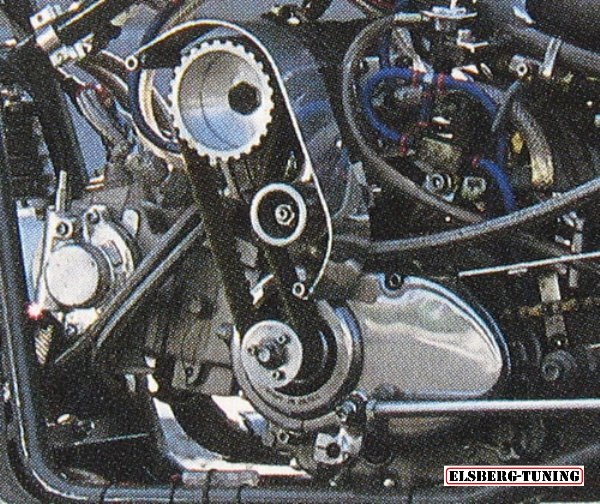

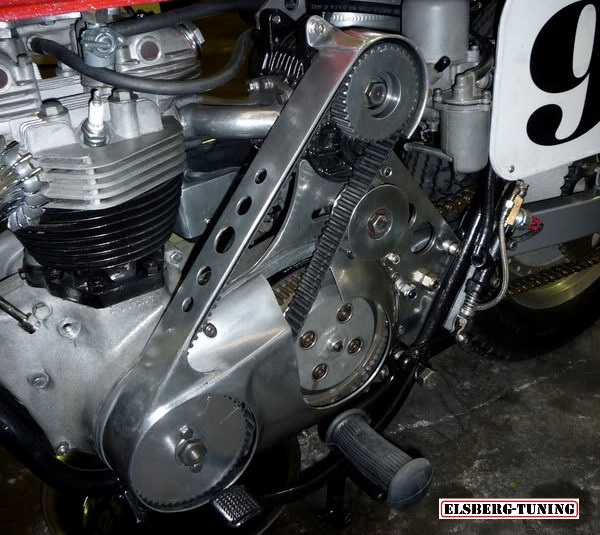

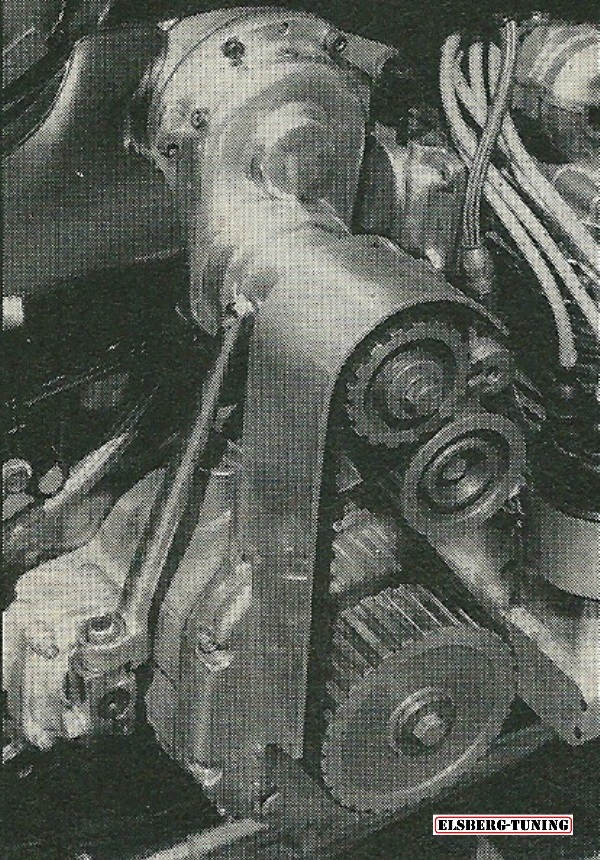

| There are many different ways to drive your supercharger, but these small pumps do not require that much to be turned. The biggest load takes place during acceleration/ deceleration, and that is mainly down to the rotating mass inside the pump. Superchargers has been known to be driven by: Gears: Mostly seen on factory installations where a cast- in supercharger ran at a pre- calculated rpm. Chains V-belts Toothed belts Multi- rib belts Hereby follows examples of above | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

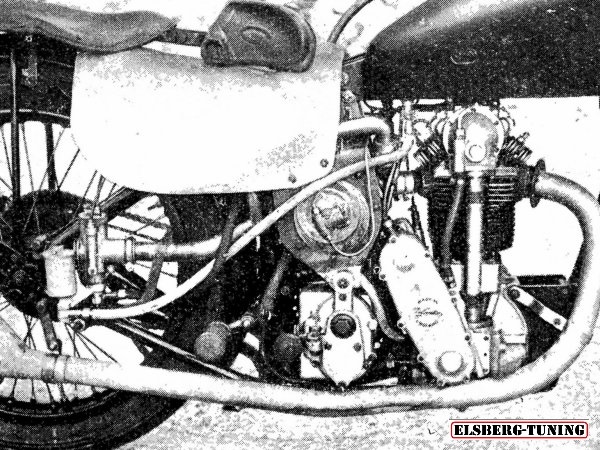

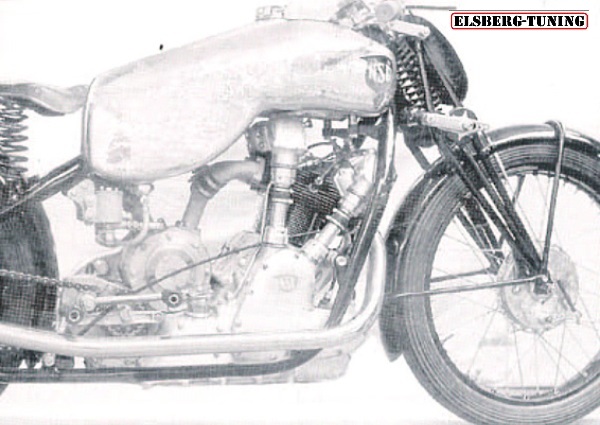

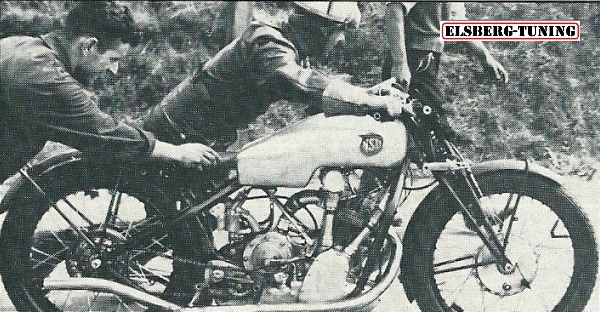

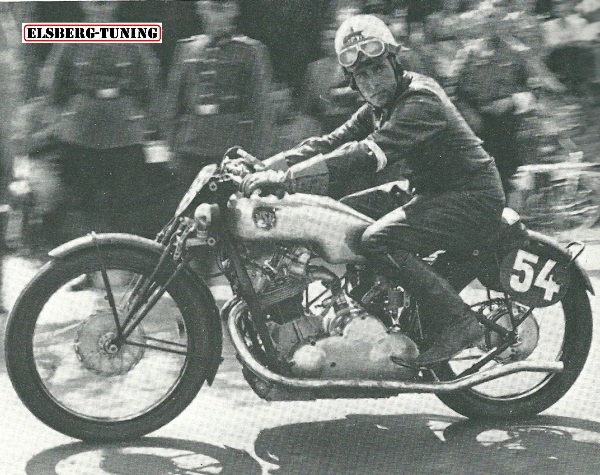

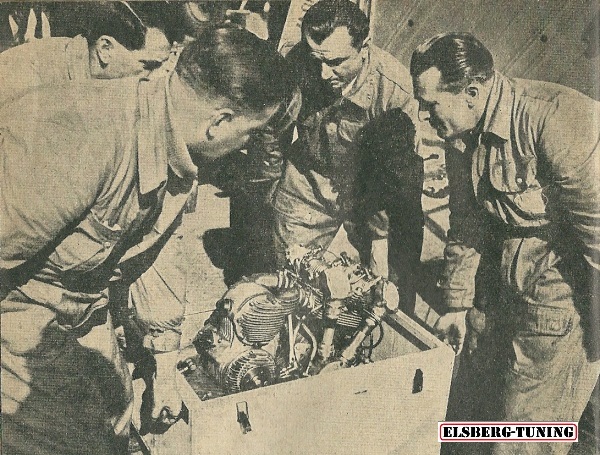

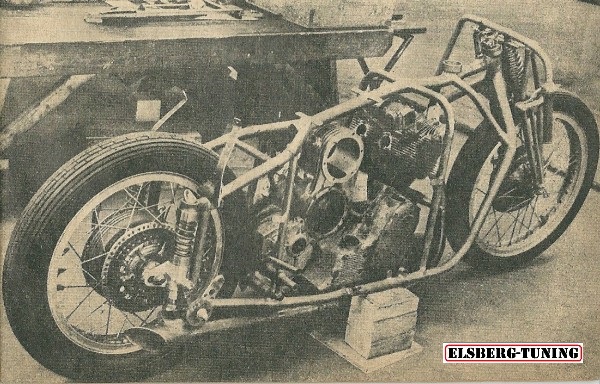

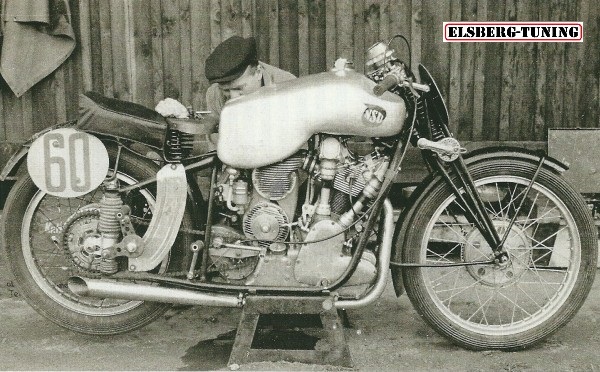

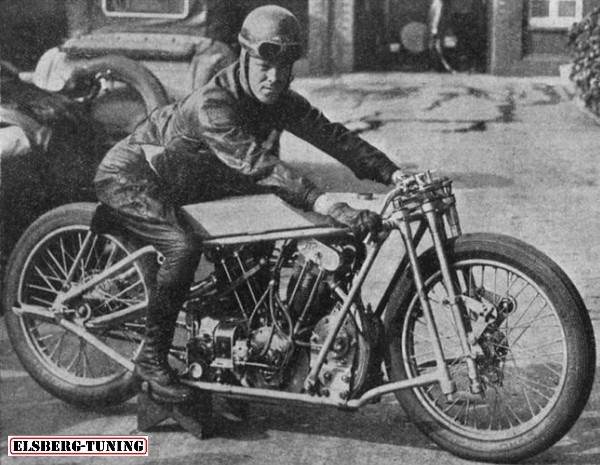

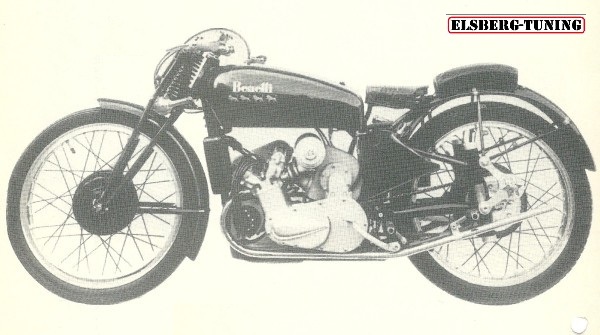

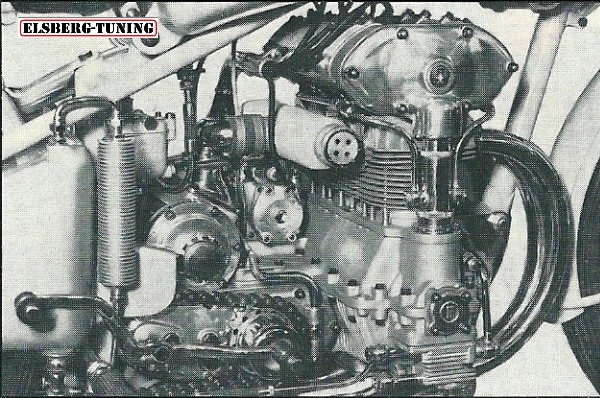

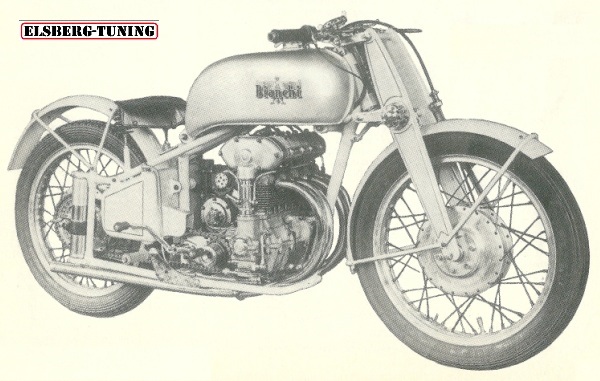

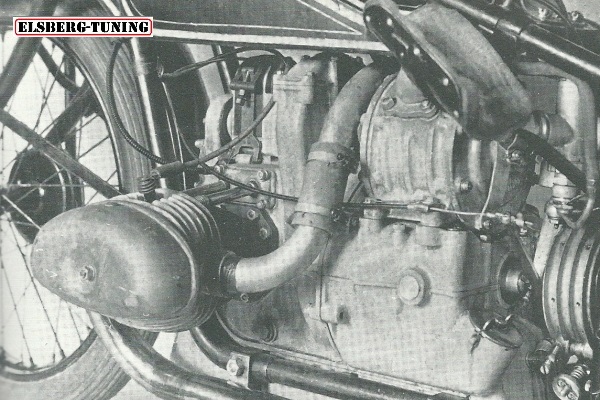

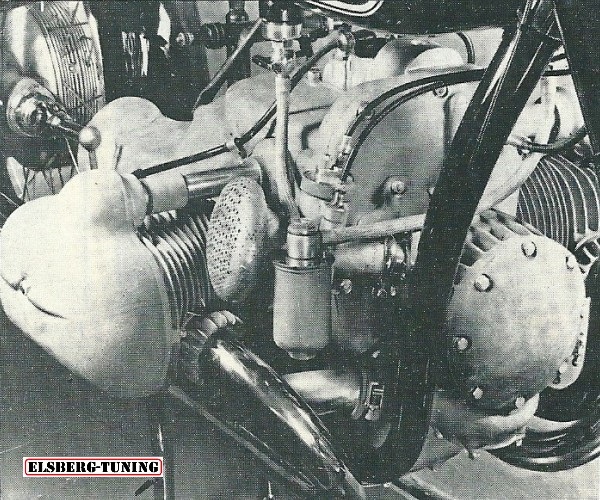

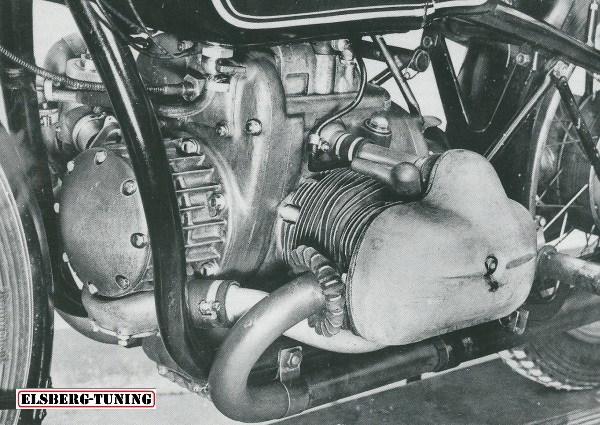

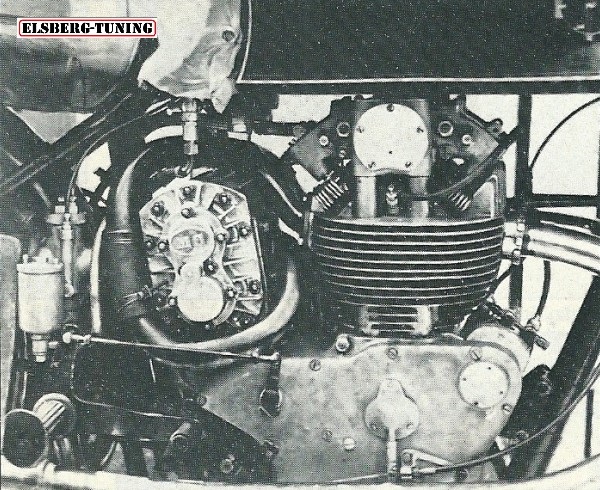

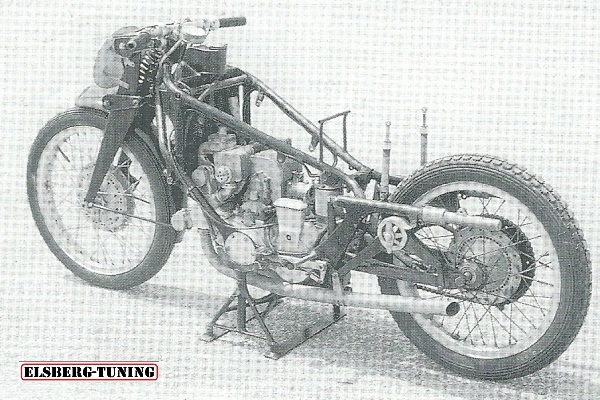

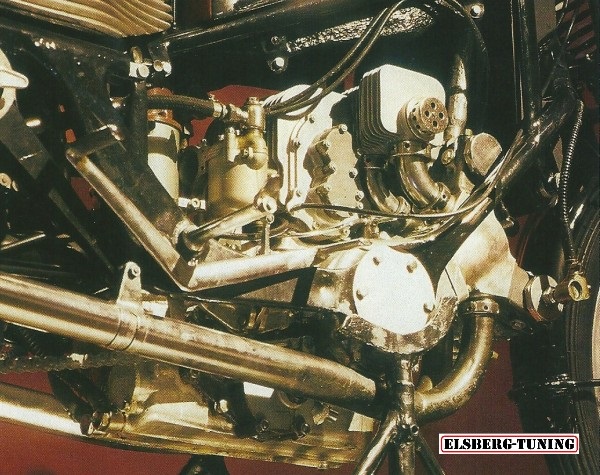

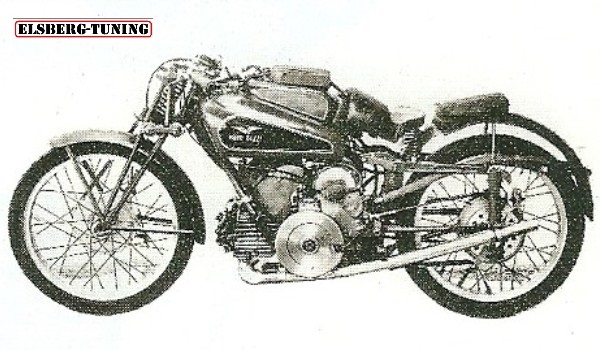

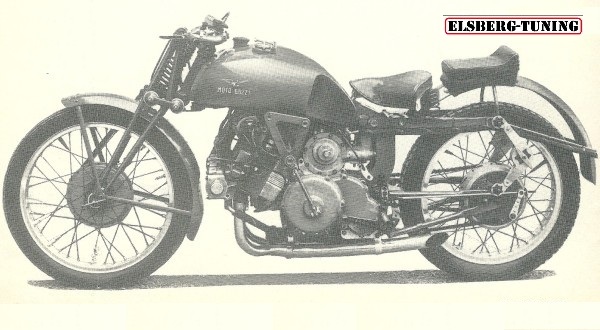

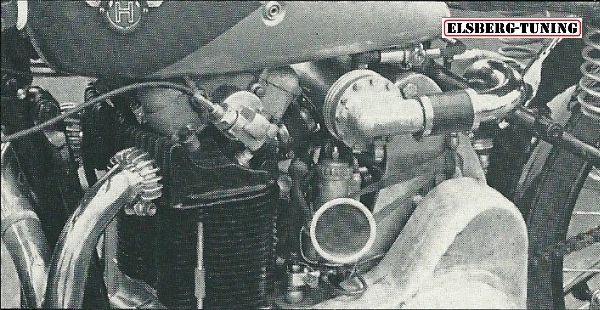

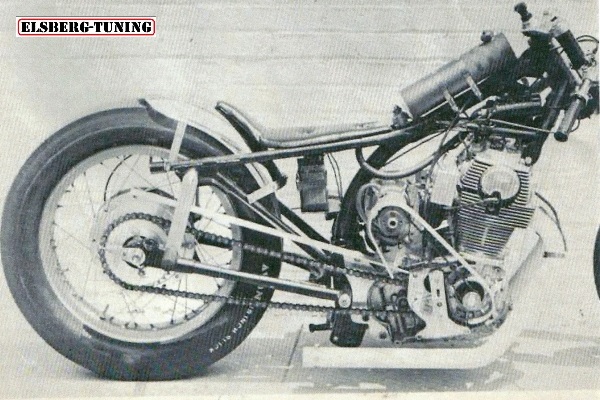

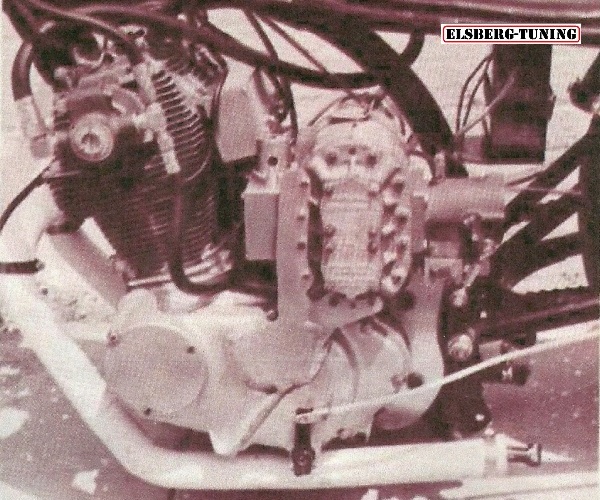

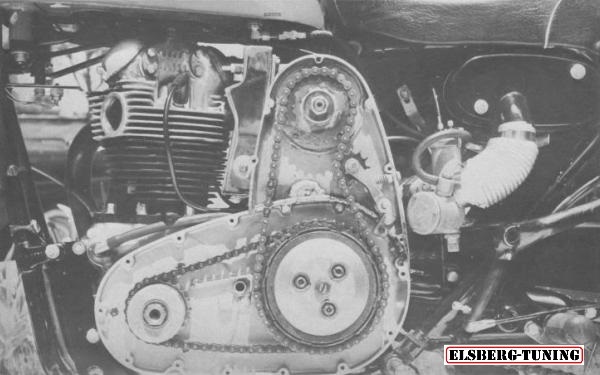

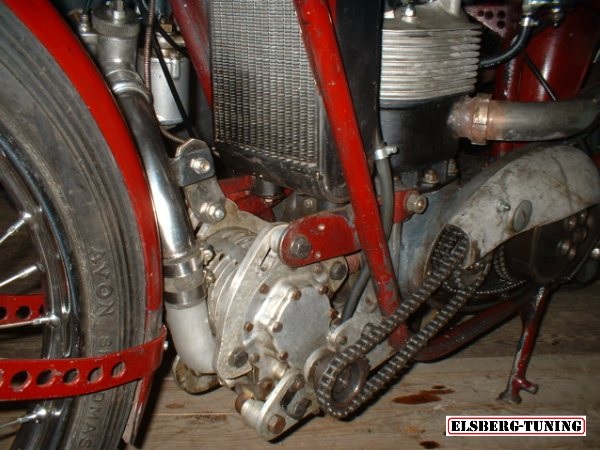

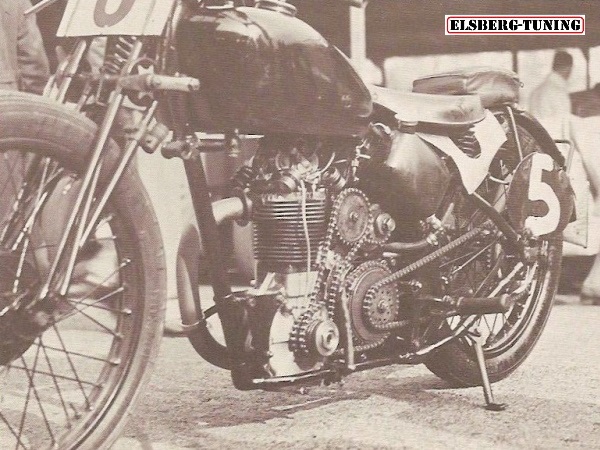

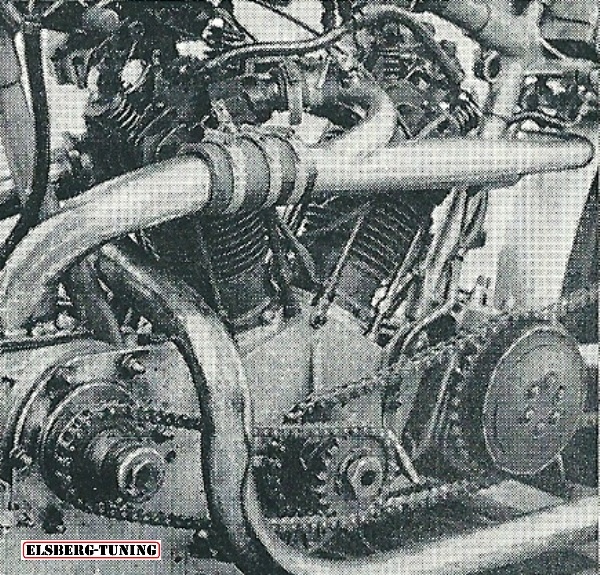

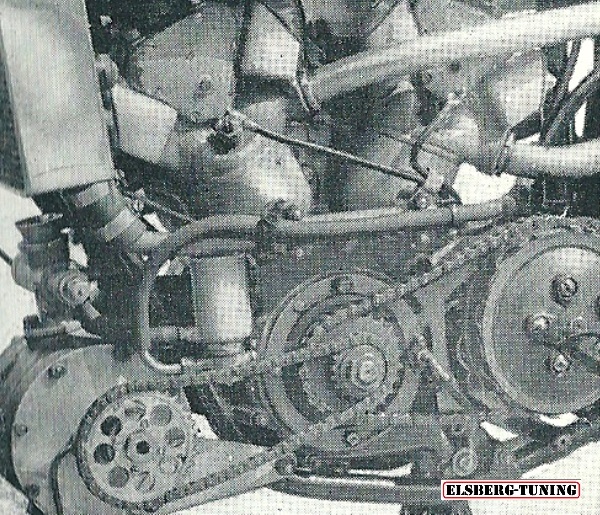

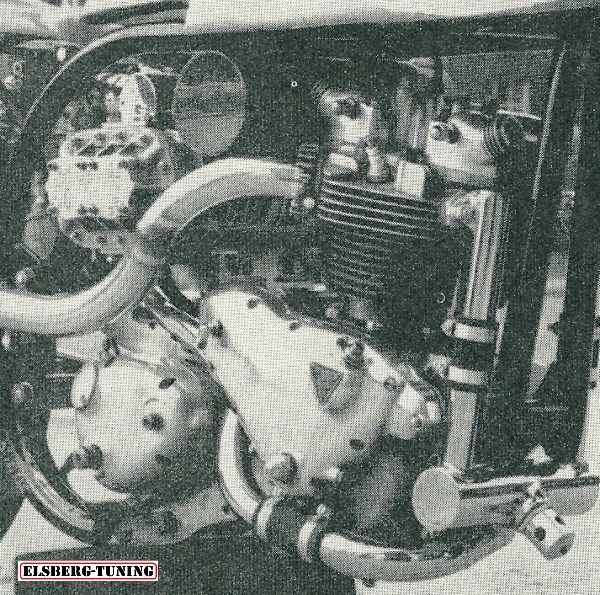

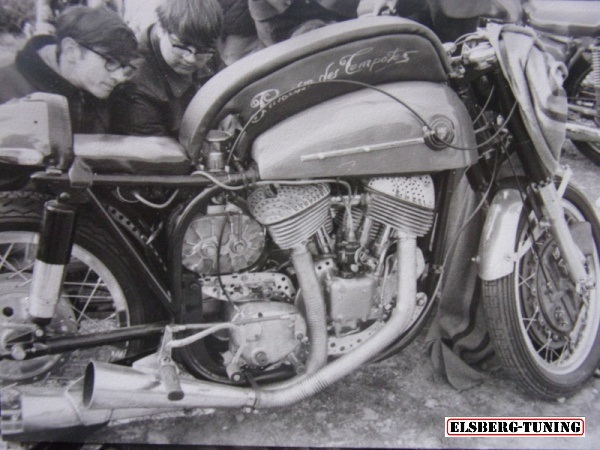

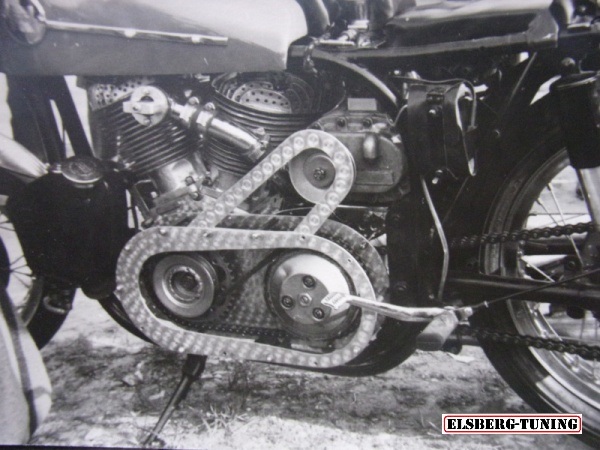

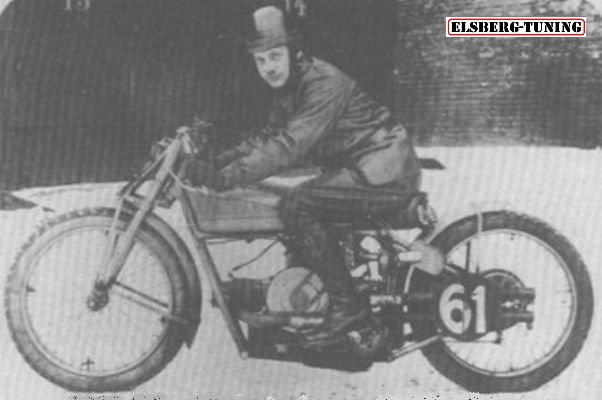

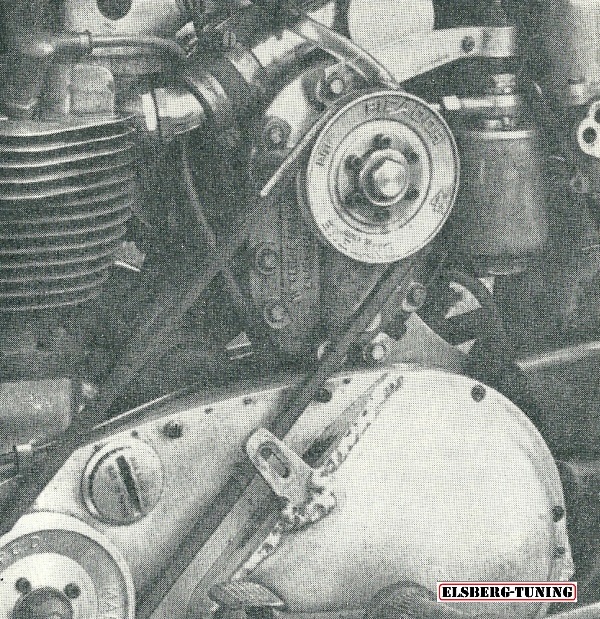

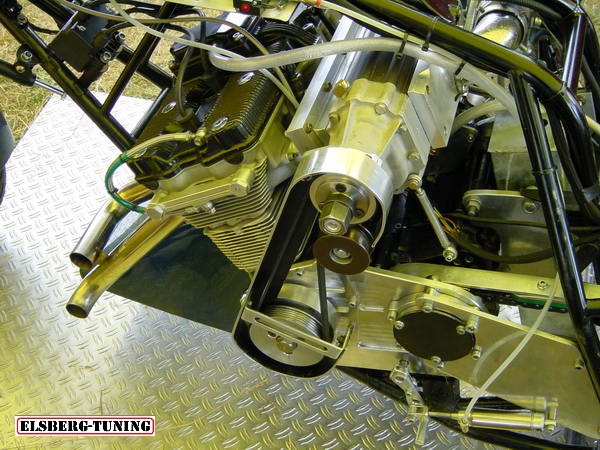

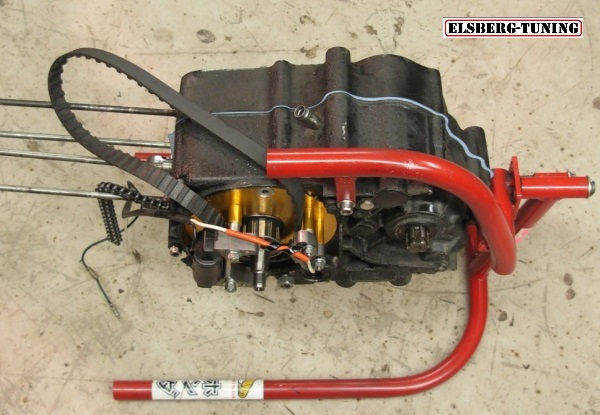

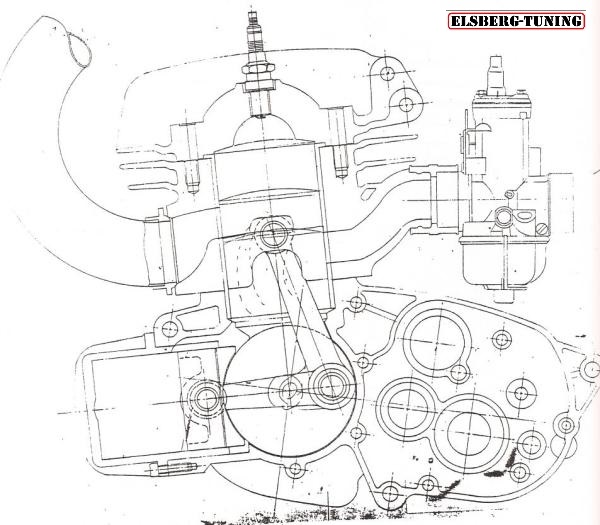

Examples of chain- driven superchargers: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

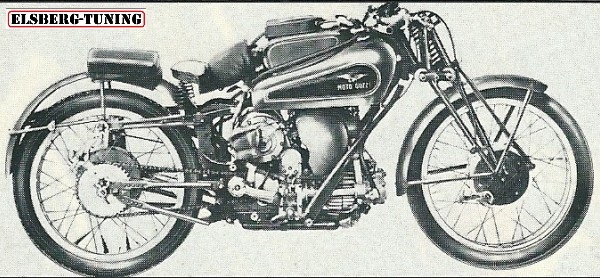

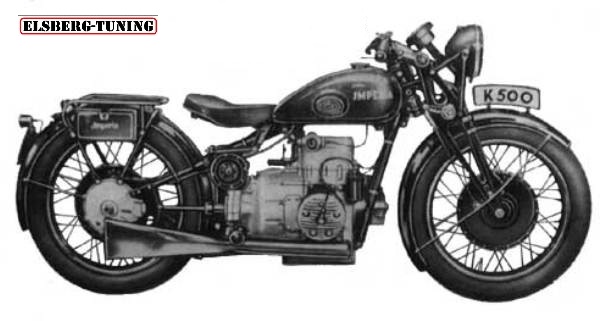

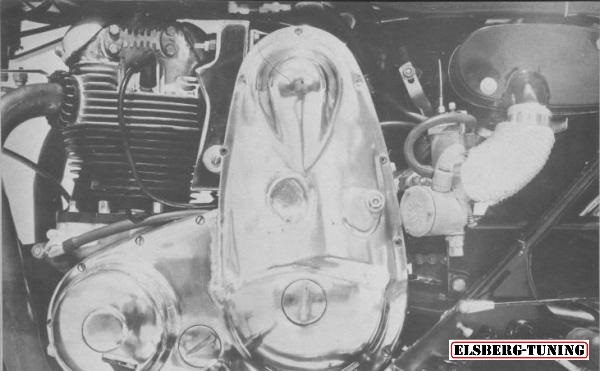

V- belt driven superchargers:  |

|

|

|

|

|

Toothed- belt drives:  |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

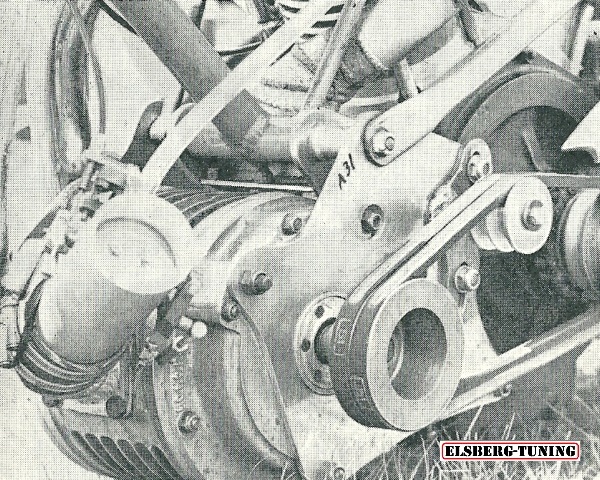

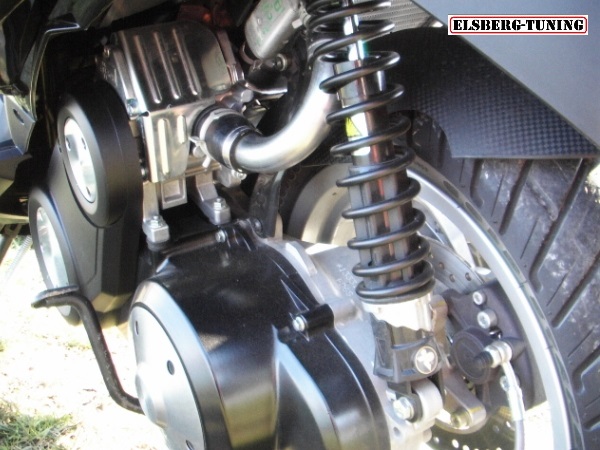

Poly- or multi- rib beltdrives: |

|

|

|

|

|

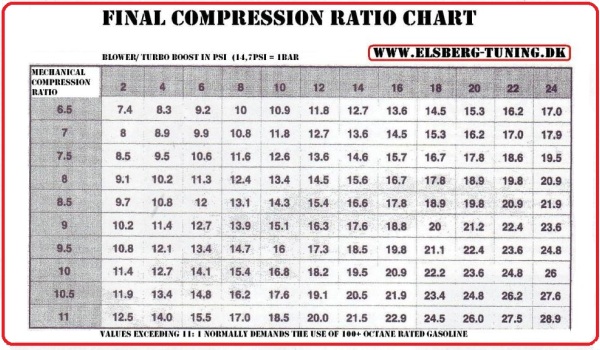

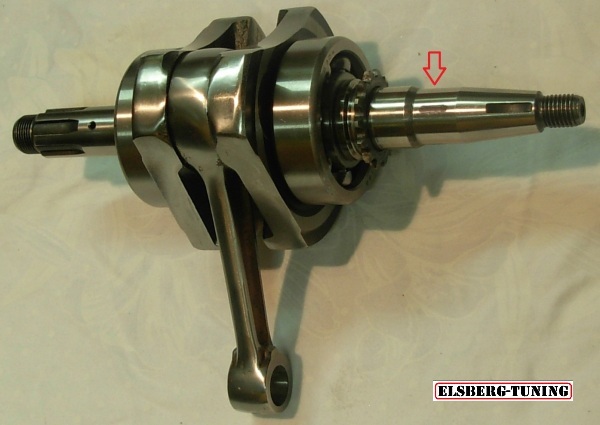

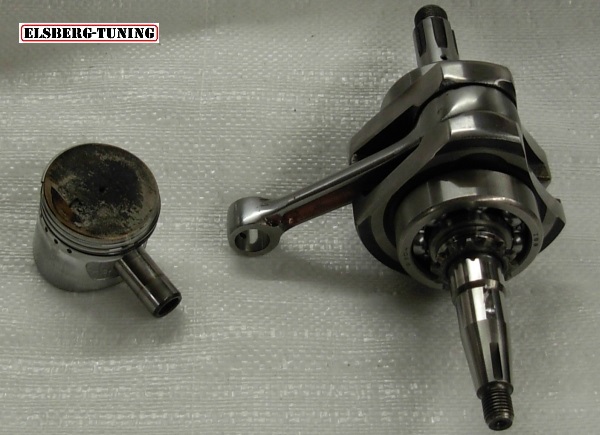

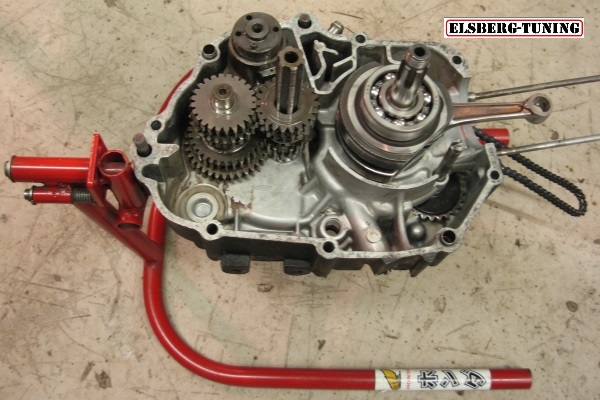

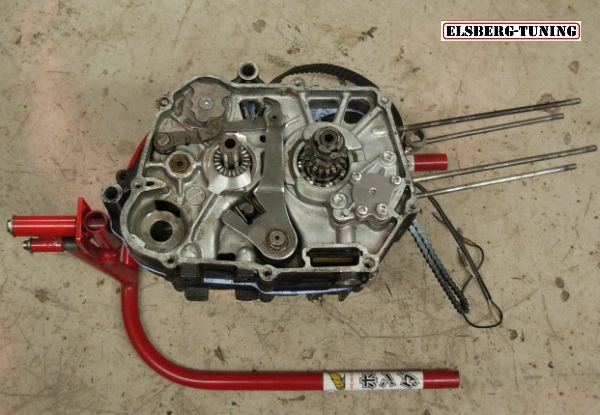

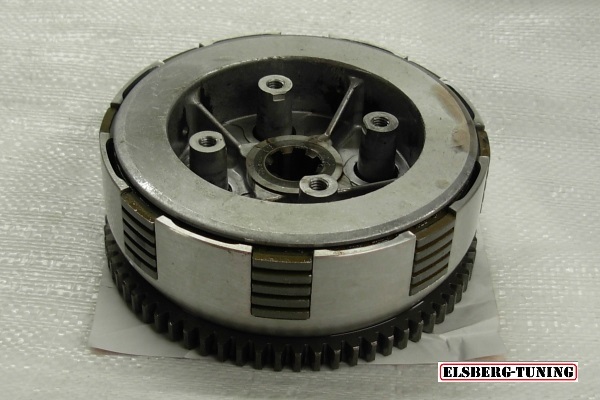

The engine which is about to be supercharged must be in good condition, preferrable rebuilt to factory tolerances. If your engine has a problem, be it overheating, oilconsumption, or a slipping clutch, then that problem will be multiplied in supercharged form. A stock engine will respond really well to low- pressure supercharging (below 9psi), if following demands are met: a compression ratio below 9: 1 a strong crank and conrod a strong clutch a good cooling system a powerful ignition system a free flowing exhaust. This list will be longer if you move on to high pressure supercharging. What happens when you supercharge an engine? The engine will no longer have to suck in the mixture by itself, and therefore becomes very responsive - xtremely responsive! A missed shift could result in over- reving the engine - meaning bent valves, so if it is possible to add an rpm- limiter, this might be a very good idea! The increase in power will make the engine run hotter, so its important that you find ways to keep it cool. |

|

|

Low pressure supercharging is not a bad thing. As you can see from chart on the left, the knock- threshold comes real close, when you exceeds 9,5: 1 CR! However, the higher the compression, the higher the effiency of the engine, so retaining the initial high CR and adding a little boost, will result in a wide torque- band. |

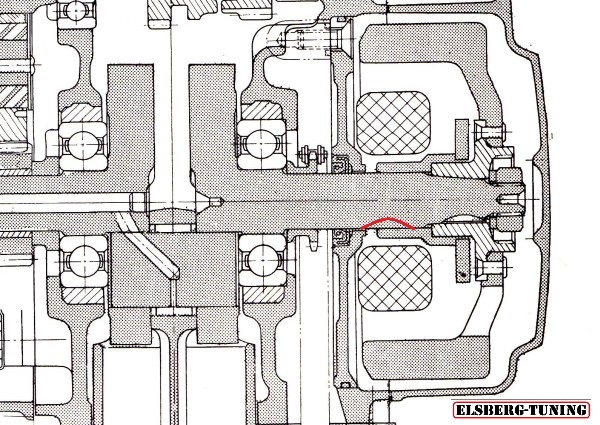

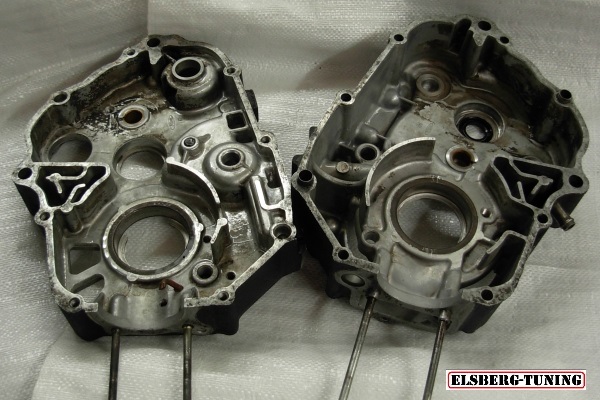

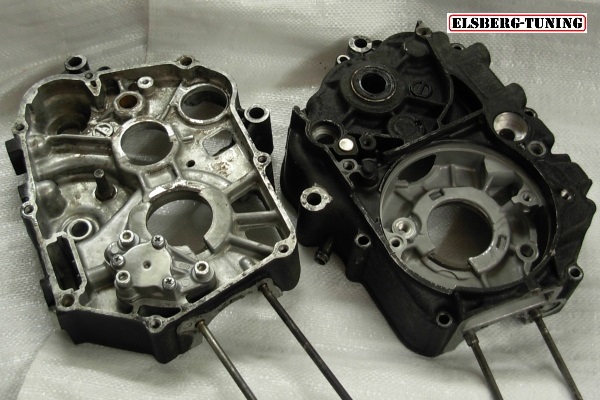

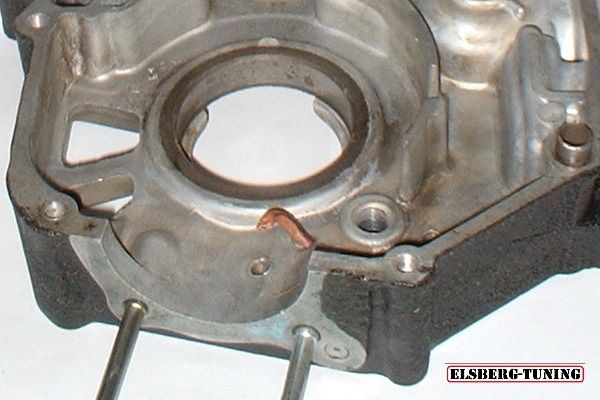

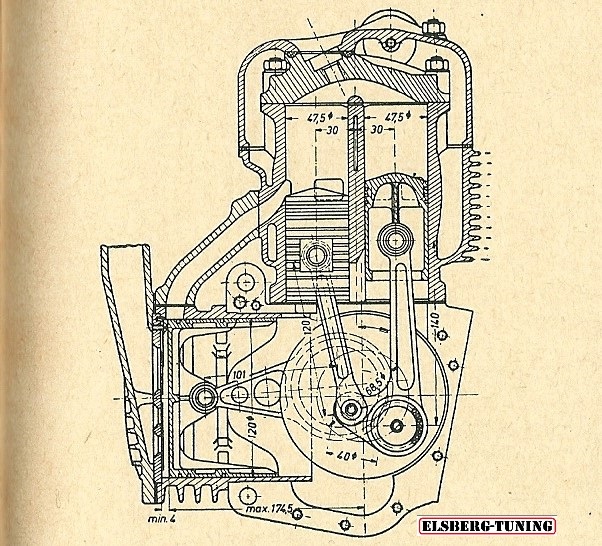

| Good planning is a must - and some technical insight! Many have asked me if the crank- mounted supercharger drive- pulley could be attached on the outside of the flywheel, making installation much easier? Well, I haven´t tried it and probably never will - these small pumps don´t take that much effort to turn, but the strain lies in the accelleration/ decelleration of the pump when throttle is activated, and that´s where you would want the load as close to the big main bearings as possible! So, room must be made for a pulley inside of the ignition, and an extra keyway must be made in the crank. |

|

|

If, and only if, you got a steady hand, it is possible to use a Dremel- type tool, to cut the keyway. Wrap entire crank in several layers of cloth with axleshaft poking through, before any grinding. When the correct depth has been reached, square- off grinder disc against a hardened piece of metal, to get the sharp corners needed. Works for me! |

|

As you can see, the pulley location will be outside the oilseal which is mounted in the ignition- baseplate, and if crank- pulley was mounted outside of flywheel, the distance to the bearing would be nearly doubled! That could lead to a breakage over time. Later type engines (12Volt) has a longer axleshaft making room for an electric start arrangement, and some even has an out- ward facing flywheel. These wide engines has a cover- mounted stator, and in one instance, I placed a supercharger- drive instead of the starters clutch- unit. |

|

|

|

|

|

|

|

|

|

|

|

|

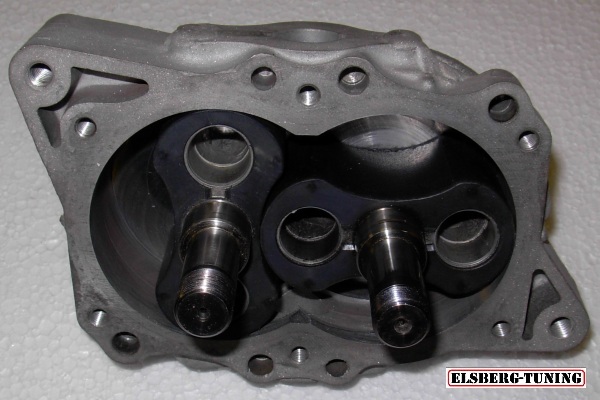

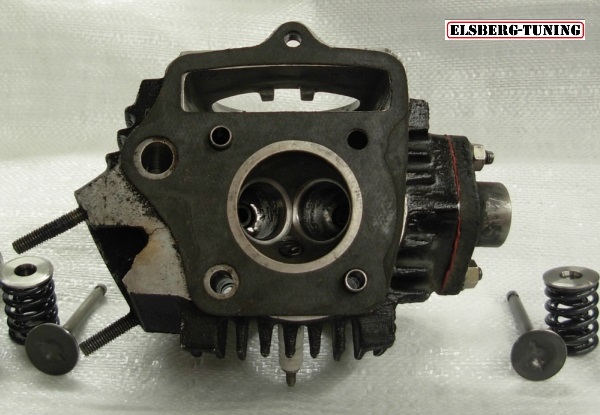

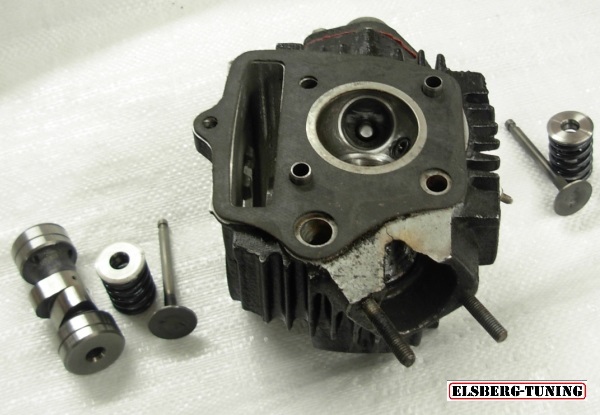

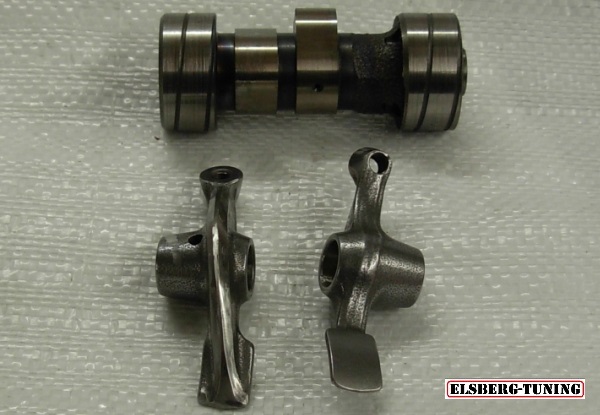

| Original CD50 cylinderhead. Biggest issue with these heads are the rather flat valve- angle caused by the 39mm bore. This wide angle have caused me a lot of trouble - even the slightest valve- float (above 12500rpm) and the valves touch each other! Took me some time to understand what was going on here! Upon disassembly small marks in piston showed contact with exhaust- valve, but only because exhaust valve were delayed in its motion by opening intake valve! I dont believe the larger heads (65cc and larger) have the same problem as the valve angle are steeper. |

|

|

|

|

|

|

|

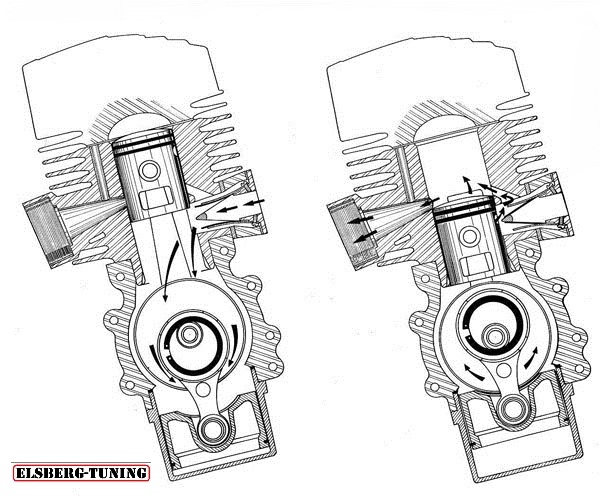

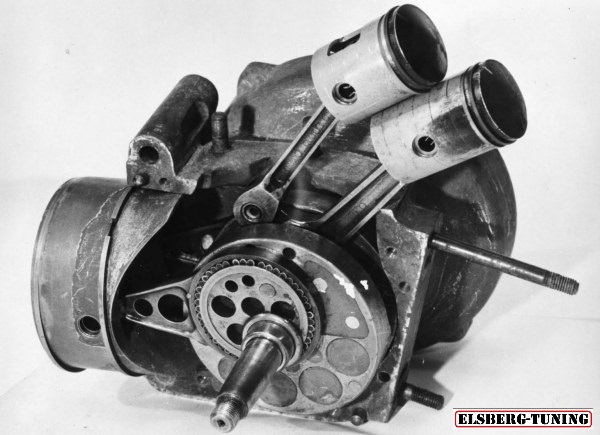

| What happens when you add a supercharger to a two- stroke engine? Will horsepower and torque be increased? YES, but if we are talking about a symmetrical two- stroke, the supercharger will just work as a scavenge pump! The raise in output comes from the pumps ability to flush all remains of the former combustion and leave the chamber filled with a hundred percent fresh charge mixture. Some low boost- pressure can be achieved in some cases, but hardly recognised as a "supercharge" due to the fact that the exhaust port remains open after the transfers closes. And that is the downside of supercharging a symmetrical two stroke engine as throughout the rpm range, a lot of this fresh charge will continue right through the exhaust unburned, and leave you with a horrendous fuel consumption. Fitting a well designed expansion chamber to such a setup will remedy the situation to a certain degree. That is when the arrangement of cones and reverse cones will form a pressure- wave, that at the right moment will reverse flow into the port just before its closed by the rising piston. Some people do in fact regard the expansion chamber as a "back- door" super- charger, but as it only functions properly in a certain rpm- range, it is not really comparable to a scavenge- pump/ supercharger. Those two in unison however, will reward you with a strong setup. If we look back in history, we will detect some very succesful supercharged two- strokes like DKW and Puch, and these had engines of the asymmetric variety. A seperate valve controlling intake timing is what is needed to really get going. |

|

|

|

|

|

|

|

|

|

|

|