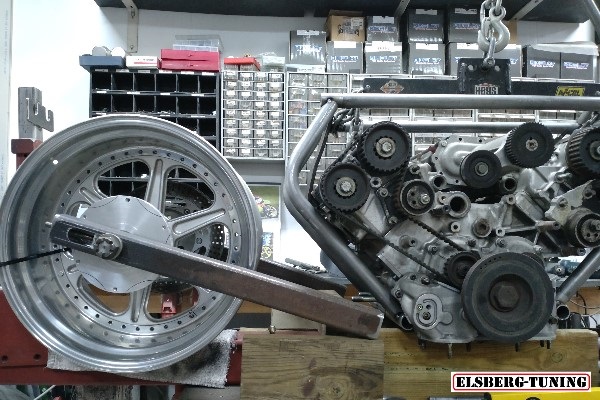

V8 custom bike project

| Many years ago I started gathering parts for a V8 custom bike. Saved the 200hp Buick/ Rover all- aluminum V8 out of the V8VW- project for this purpose, but a Swede beat me to it! Rolf Andersson did a perfect job on his Sidewinder V8- bike and that challenge sort of fainted!!! But now the V8 bike project is very much alive again, with the purchace of another all- aluminum V8 engine. A smaller in size 3Litre Quattrovalvole 4- cam V8, designed by Ferrari - a beautiful piece of engineering sounding fantastic when it reach its 7000rpm redline. Really look forward to build that one :o) |

|

| 2021 Update: The periods of isolation during the Covid19 pandemic have "forced" me to spend more time in the garage :o) Many projects are finished and next in line is the V8 bike. The many parts gathered through the years have been unboxed and readied. |

|

|

|

|

|

|

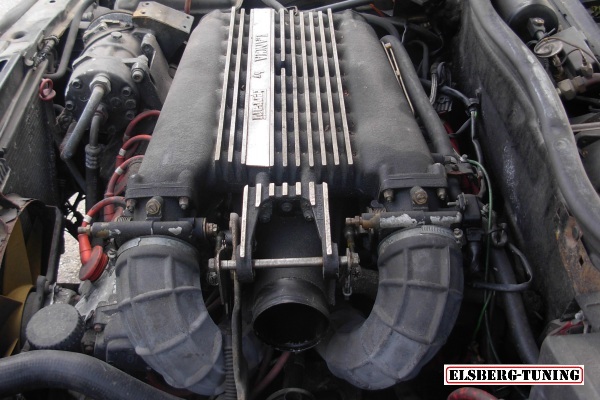

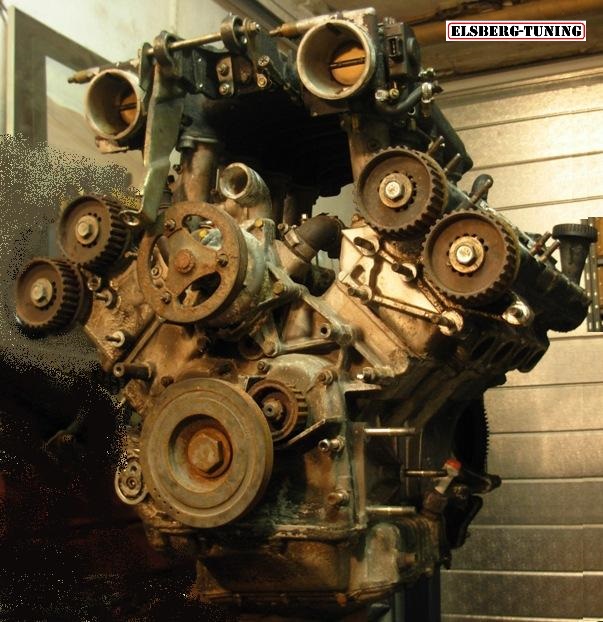

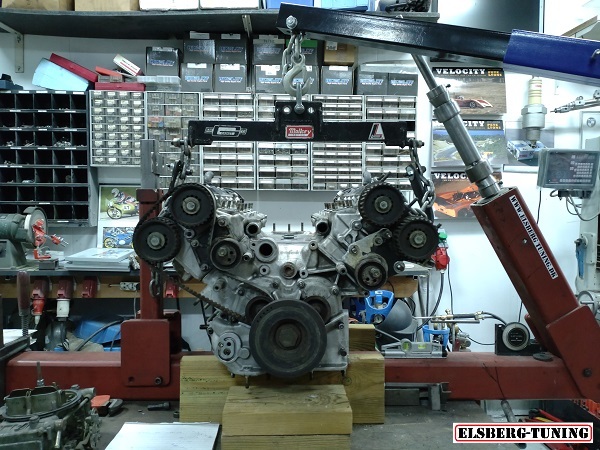

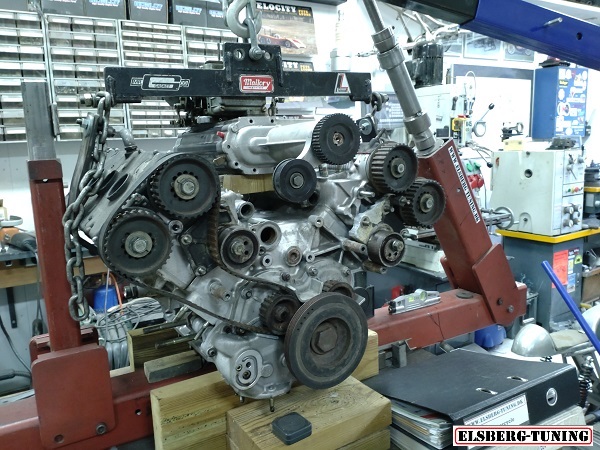

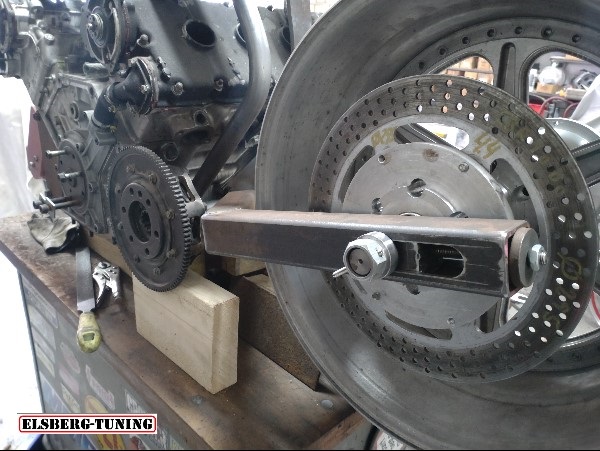

History of this engine: It was pulled from a 1989 Lancia Thema 8.32. Engine designation are F105L which tells us that this is a variant of the Ferrari 308 quattrovalvole 3L V8. The L for Lancia meant it was altered in characteristics, from sportscar to limousine engine, operating at a lower rpm. This was done by exchanging the usual 180° flat- plane crankshaft with a 90°, more normal for a V8, together with smaller valves in the cylinder- heads and ofcourse, different camshaft timing. This resultet in a more docile torquey engine emitting the usual burble expected from a 90° V8. Being a 1989 version means it is from the second series, and thus issued with emission- control. Also the last year for F105L engines being assembled by Ferrari, where the 1990- 92 V8´s were assembled at Ducati´s plant. |

|

|

|

|

|

|

|

|

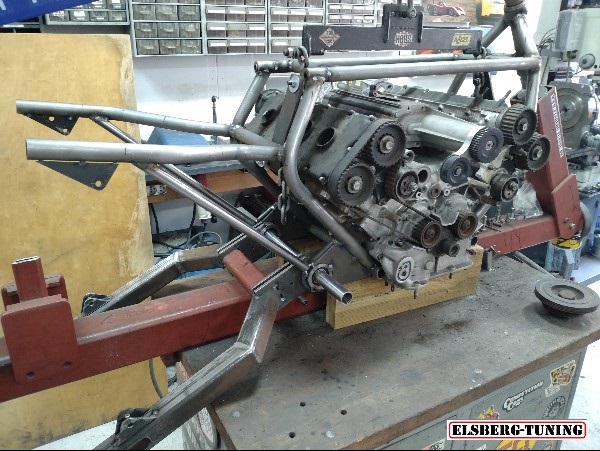

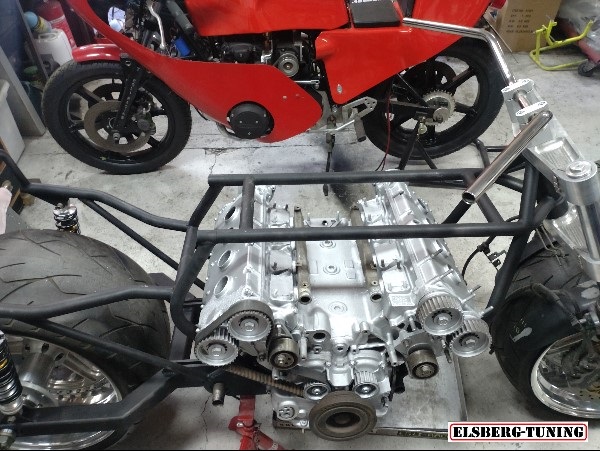

| Thoughts around making of the frame: Initially I planned a double cradle tube frame, but with the engine being this bulky, it had to be tight- fitting nessecitating an assembly of two sections. One could also use the engine as a carrying member. Here I must say I´m very inspired by the work of the brilliant Allen Millyard: Millyard on Youtube The way he managed to make a rideable motorcycle powered by a massive Viper V10 car engine.... |

|

|

|

|

|

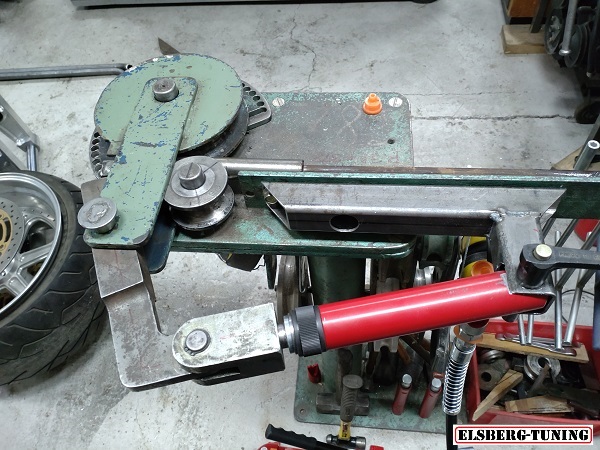

| Had to modify the mandrel- tube bender. Going from 20x2mm to 30x3 DOM- tubes meant that an increase in leverage was nessecary. Hydraulic actuation is the way to go. |

|

|

|

|

|

|

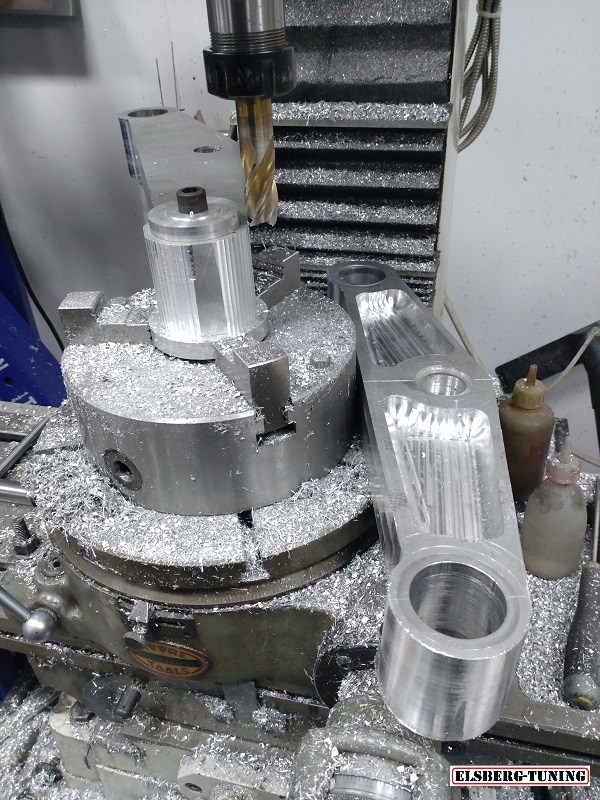

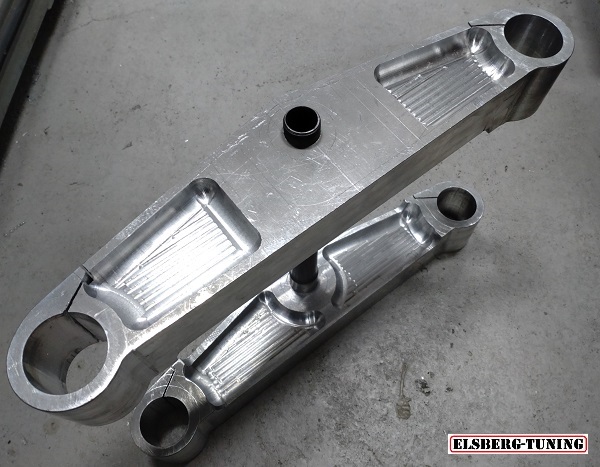

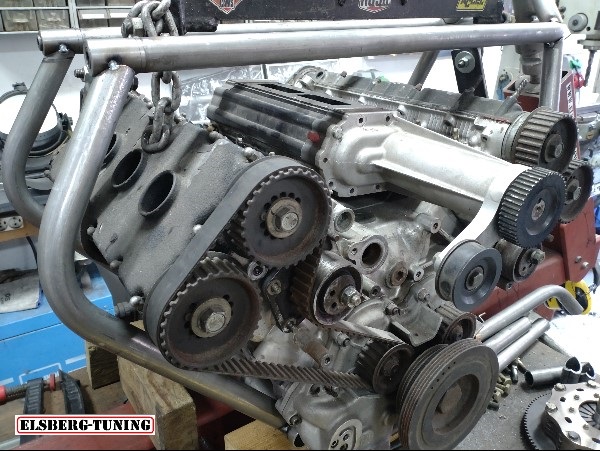

The engine acts as a load-bearing element. The design of the frame is unconditionally laid out with a view to optimal routing of the exhaust pipes. A supercharged engine needs a free- flowing exhaust. |

|

|

|

|